Modern cable design has evolved significantly over the past decades, driven by the need for cost-effective yet reliable electrical conductors. Among the most innovative solutions that have emerged is copper clad aluminum, a composite material that combines the best properties of both metals. This advanced conductor technology addresses many challenges faced by engineers and manufacturers in today's competitive electrical industry, offering a balanced approach to performance and economics.

The electrical industry constantly seeks materials that can deliver superior performance while maintaining cost efficiency. Copper clad aluminum represents a strategic compromise that leverages the excellent electrical properties of copper with the lightweight and economical advantages of aluminum. This innovative conductor design has found widespread adoption across numerous applications, from telecommunications infrastructure to power transmission systems.

Understanding the fundamental principles behind copper clad aluminum technology reveals why this material has become increasingly popular in modern cable manufacturing. The composite structure provides enhanced conductivity compared to pure aluminum while remaining significantly more affordable than solid copper conductors. This balance makes it an attractive option for projects where budget constraints must be balanced against performance requirements.

Engineering Principles Behind Copper Clad Aluminum Design

Structural Composition and Manufacturing Process

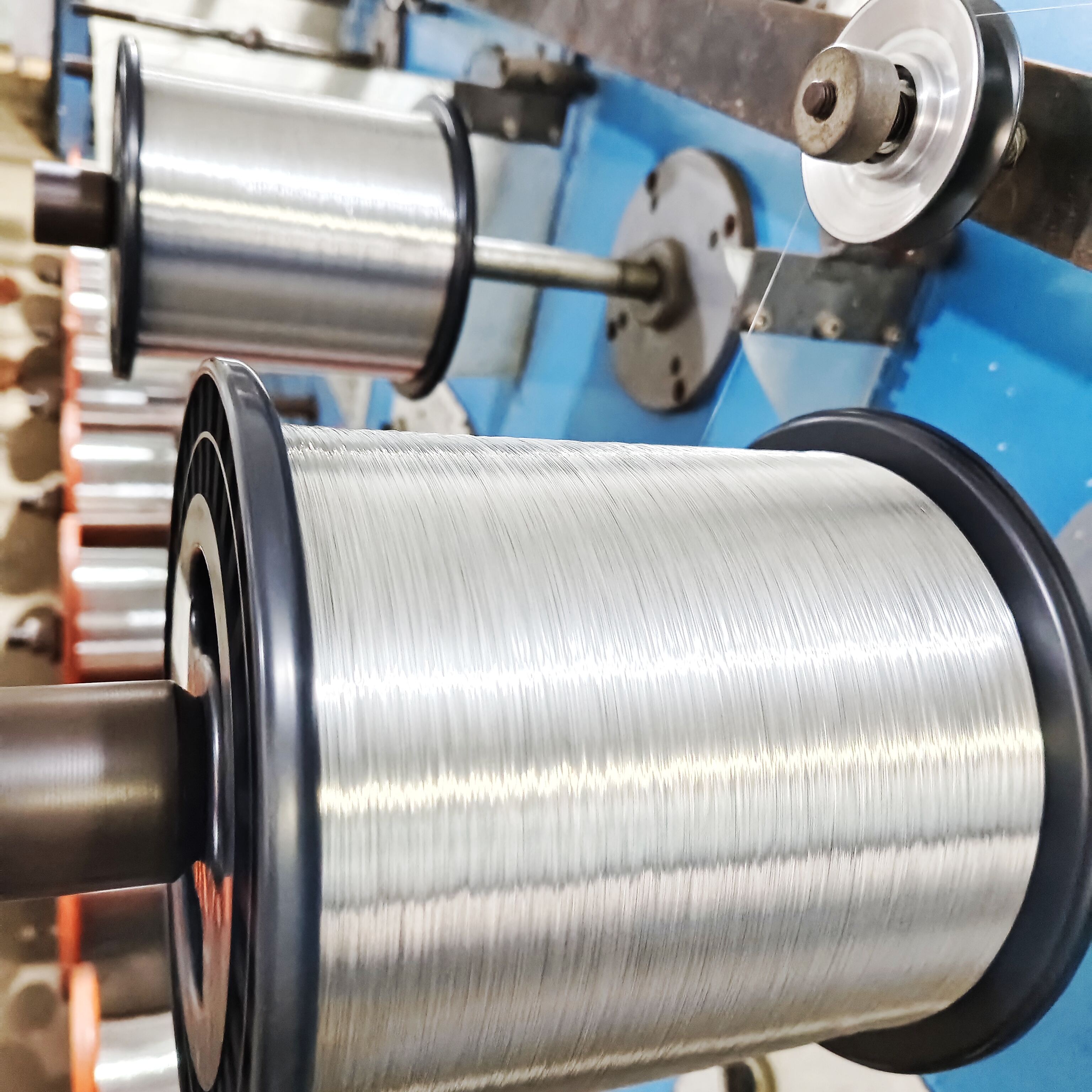

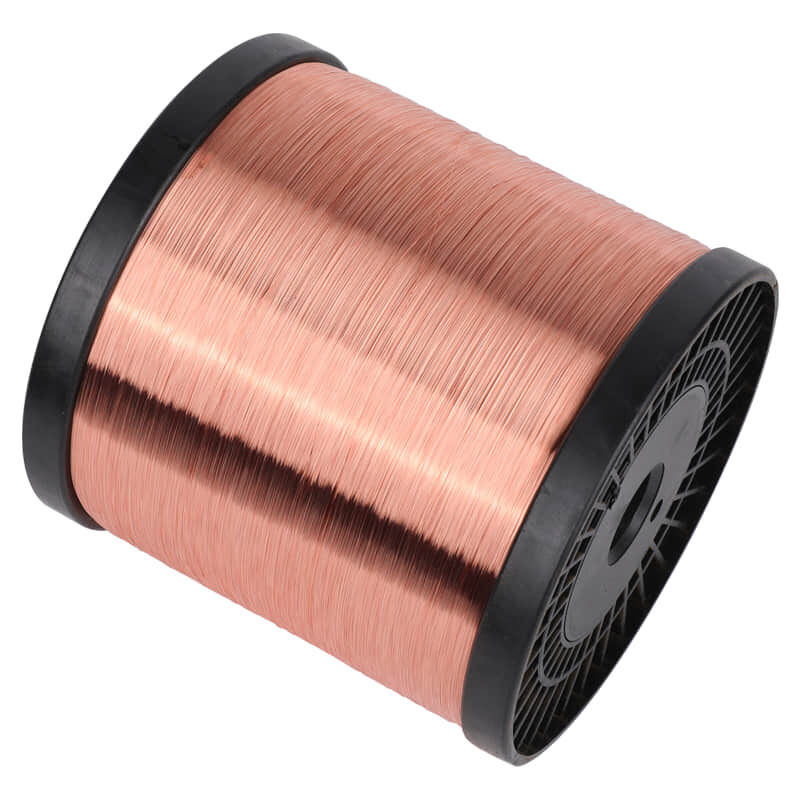

The manufacturing process of copper clad aluminum involves sophisticated metallurgical techniques that create a permanent bond between the copper exterior and aluminum core. This process typically employs either electroplating or cladding methods, where a thin layer of high-purity copper is applied to an aluminum substrate. The resulting conductor maintains the structural integrity of aluminum while benefiting from copper's superior surface conductivity properties.

Advanced manufacturing techniques ensure that the copper layer adheres uniformly to the aluminum core, creating a reliable electrical interface. The thickness of the copper cladding can be precisely controlled to optimize performance characteristics for specific applications. This customizable approach allows manufacturers to tailor copper clad aluminum products to meet diverse industry requirements while maintaining consistent quality standards.

Quality control measures during production include rigorous testing of the bond integrity between copper and aluminum layers. These tests verify that the composite material can withstand mechanical stress, thermal cycling, and environmental conditions without delamination or performance degradation. Such comprehensive quality assurance ensures that copper clad aluminum conductors deliver reliable long-term performance in demanding applications.

Electrical Performance Characteristics

The electrical properties of copper clad aluminum combine the high conductivity of copper at the surface with the cost-effective core of aluminum. The copper cladding primarily carries the electrical current due to the skin effect, where alternating current tends to flow near the surface of conductors. This phenomenon makes copper clad aluminum particularly effective for AC applications, where the copper layer handles the majority of current transmission.

Conductivity measurements show that copper clad aluminum achieves approximately 60-65% of solid copper's conductivity while maintaining significantly lower weight and material costs. For many applications, this conductivity level exceeds the minimum requirements, making it an optimal choice for cost-sensitive projects. The performance characteristics remain stable across a wide range of operating temperatures and environmental conditions.

Impedance characteristics of copper clad aluminum cables can be precisely engineered to match specific requirements. The composite structure allows for fine-tuning of electrical parameters through variations in copper layer thickness and aluminum core dimensions. This flexibility enables manufacturers to optimize cables for particular frequency ranges or impedance specifications without compromising overall performance.

Economic Advantages in Cable Manufacturing

Material Cost Optimization

The economic benefits of copper clad aluminum stem primarily from the significant cost difference between copper and aluminum raw materials. Aluminum costs substantially less than copper, and since it forms the majority of the conductor's volume, the overall material cost reduction can be dramatic. This cost advantage becomes particularly pronounced in large-scale cable installations where material expenses represent a significant portion of total project costs.

Market volatility in copper prices has made cost predictability challenging for cable manufacturers and end users. Copper clad aluminum provides a buffer against these price fluctuations since aluminum prices tend to be more stable and predictable. This stability allows for more accurate project budgeting and reduces the risk associated with material cost escalation during long-term contracts.

Manufacturing efficiency improvements also contribute to the economic advantages of copper clad aluminum. The lighter weight of these conductors reduces transportation costs, handling expenses, and installation labor requirements. These secondary cost savings can accumulate to significant amounts, especially in large infrastructure projects where thousands of feet of cable must be transported and installed.

Long-term Value Proposition

The durability and longevity of copper clad aluminum cables contribute to their long-term economic value. Properly manufactured and installed copper clad aluminum systems can provide decades of reliable service with minimal maintenance requirements. The copper cladding protects the aluminum core from oxidation and corrosion, extending the operational lifespan of the conductor significantly.

Energy efficiency considerations also factor into the long-term value equation. While copper clad aluminum may have slightly higher resistance than solid copper, the difference is often negligible in practical applications. For many installations, the energy losses associated with this small resistance increase are far outweighed by the initial cost savings and reduced installation expenses.

Maintenance costs for copper clad aluminum installations typically remain low throughout the service life of the cable. The stable electrical properties and robust construction minimize the need for replacement or repair, contributing to lower total cost of ownership. This reliability makes copper clad aluminum an attractive option for critical infrastructure where service interruptions must be minimized.

Applications Across Multiple Industries

Telecommunications Infrastructure

Telecommunications applications represent one of the largest markets for copper clad aluminum conductors. The material's excellent high-frequency performance characteristics make it ideal for coaxial cables used in cable television, broadband internet, and cellular communication systems. The skin effect at these frequencies ensures that the copper cladding carries virtually all the signal, delivering performance comparable to solid copper conductors.

Network infrastructure projects benefit significantly from the weight reduction provided by copper clad aluminum cables. Lighter cables reduce structural loading on towers, buildings, and underground conduits, potentially allowing for simplified support structures and installation methods. This weight advantage becomes particularly important in aerial installations where mechanical stress on supporting structures must be minimized.

The reliability requirements of telecommunications infrastructure demand conductors that maintain consistent performance over long periods. Copper clad aluminum has proven its ability to meet these demanding requirements, with many installations providing years of trouble-free service. The material's resistance to environmental degradation ensures signal integrity remains stable throughout the cable's operational life.

Power Transmission and Distribution

Power transmission applications for copper clad aluminum span from residential wiring to medium-voltage distribution systems. The conductor's ability to handle substantial current loads while maintaining cost-effectiveness makes it attractive for utility companies and electrical contractors. Proper sizing and installation techniques ensure that copper clad aluminum power cables meet all safety and performance standards.

Overhead power lines represent another significant application area where copper clad aluminum provides compelling advantages. The reduced weight of these conductors allows for longer spans between support structures, potentially reducing installation costs and improving system reliability. The aluminum core provides excellent strength-to-weight characteristics while the copper cladding ensures reliable electrical contact at connection points.

Underground power distribution systems also benefit from copper clad aluminum technology. The corrosion resistance provided by the copper cladding protects against underground environmental conditions that might otherwise degrade aluminum conductors. This protection extends cable life and reduces the need for preventive maintenance in buried installations.

Technical Performance Considerations

Thermal Management Properties

Thermal characteristics of copper clad aluminum cables require careful consideration in design and installation applications. The thermal expansion coefficients of copper and aluminum differ slightly, but proper manufacturing techniques ensure that this difference does not compromise the integrity of the composite conductor. Temperature cycling tests demonstrate that well-manufactured copper clad aluminum maintains its electrical and mechanical properties across a wide temperature range.

Heat dissipation capabilities of copper clad aluminum conductors compare favorably with other conductor materials. The aluminum core provides excellent thermal conductivity, helping to distribute heat generated by current flow throughout the conductor cross-section. This thermal distribution helps prevent hot spots that could potentially damage the cable insulation or compromise system reliability.

Current-carrying capacity calculations for copper clad aluminum must account for the specific thermal and electrical properties of the composite material. Engineering standards provide guidelines for determining appropriate conductor sizes based on load requirements, ambient conditions, and installation methods. Following these standards ensures that copper clad aluminum installations operate safely and efficiently throughout their design life.

Environmental Durability Factors

Environmental testing of copper clad aluminum demonstrates excellent resistance to common degradation mechanisms. The copper cladding provides a protective barrier against atmospheric corrosion, moisture intrusion, and chemical exposure. This protection is particularly important in harsh environments where pure aluminum conductors might experience accelerated deterioration.

UV resistance testing shows that copper clad aluminum maintains its properties when exposed to sunlight and outdoor conditions. The copper surface does not significantly degrade under UV exposure, ensuring that aerial installations maintain their electrical and mechanical integrity. This durability reduces maintenance requirements and extends service life in outdoor applications.

Moisture resistance characteristics of copper clad aluminum exceed those of pure aluminum due to the protective copper layer. The composite structure prevents moisture from reaching the aluminum core, eliminating the risk of galvanic corrosion that can occur when aluminum comes into contact with other metals in the presence of moisture. This enhanced moisture resistance makes copper clad aluminum suitable for marine and high-humidity environments.

Installation Best Practices and Standards

Proper Termination Techniques

Successful installation of copper clad aluminum requires adherence to specific termination practices that account for the material's unique properties. Connection methods must ensure reliable electrical contact while preventing galvanic corrosion between dissimilar metals. Approved connectors and termination hardware specifically designed for copper clad aluminum applications should always be used to ensure long-term reliability.

Cleaning procedures for copper clad aluminum terminations differ from those used with solid copper conductors. The copper surface should be prepared using appropriate abrasives and cleaning compounds that remove oxidation without damaging the underlying aluminum core. Proper preparation ensures optimal electrical contact and prevents connection degradation over time.

Torque specifications for copper clad aluminum connections require careful attention to manufacturer recommendations. Over-tightening can damage the composite structure, while under-tightening may result in poor electrical contact. Using calibrated torque tools and following established procedures ensures that connections meet performance and safety requirements.

Code Compliance and Safety Standards

Electrical codes and safety standards provide specific requirements for copper clad aluminum installations. These standards address conductor sizing, installation methods, termination practices, and marking requirements. Compliance with applicable codes ensures that installations meet safety requirements and receive approval from regulatory authorities.

Inspection procedures for copper clad aluminum installations should verify proper materials, correct installation techniques, and compliance with applicable standards. Regular inspections help identify potential issues before they become problems, contributing to long-term system reliability and safety. Documentation of inspections and test results provides valuable records for future maintenance activities.

Training requirements for installers working with copper clad aluminum emphasize the unique characteristics of this material and proper handling techniques. Understanding the differences between copper clad aluminum and other conductor types helps ensure successful installations and prevents common mistakes that could compromise system performance or safety.

Future Developments and Market Trends

Technology Advancement Opportunities

Research and development efforts continue to improve copper clad aluminum manufacturing processes and performance characteristics. Advanced cladding techniques promise to enhance the bond strength between copper and aluminum layers while reducing manufacturing costs. These improvements may further expand the applications where copper clad aluminum provides optimal solutions.

Nanotechnology applications in copper clad aluminum production offer potential for enhanced electrical and mechanical properties. Surface treatments and additives at the nanoscale could improve conductivity, corrosion resistance, and thermal performance. These advanced materials may open new markets and applications for copper clad aluminum technology.

Quality control innovations including real-time monitoring and automated testing systems improve the consistency and reliability of copper clad aluminum products. These manufacturing improvements reduce variability and enhance confidence in the material's performance characteristics. Better quality control also enables tighter specifications and more demanding applications.

Market Growth Projections

Industry analysts project continued growth in copper clad aluminum demand driven by infrastructure development and cost pressure in the electrical industry. Telecommunications expansion, renewable energy projects, and smart grid implementations all represent significant market opportunities. The material's cost advantages become increasingly important as project budgets face pressure from rising material and labor costs.

Geographic expansion of copper clad aluminum adoption varies by region and application. Developing markets with significant infrastructure needs represent major growth opportunities, while mature markets focus on replacement and upgrade projects. Understanding regional preferences and requirements helps manufacturers develop targeted products and marketing strategies.

Sustainability considerations increasingly influence material selection decisions, and copper clad aluminum offers advantages in this area. The reduced copper content decreases mining requirements for this limited resource, while the aluminum component is highly recyclable. These environmental benefits align with growing emphasis on sustainable construction and infrastructure development practices.

FAQ

What is the main advantage of using copper clad aluminum in cables

The primary advantage of copper clad aluminum is its ability to provide excellent electrical performance at a significantly lower cost than solid copper conductors. The copper cladding ensures superior conductivity characteristics, especially for AC applications, while the aluminum core reduces weight and material costs. This combination makes it ideal for large-scale installations where budget considerations are important but performance cannot be compromised.

How does copper clad aluminum perform compared to solid copper

Copper clad aluminum typically achieves 60-65% of solid copper's conductivity while offering substantial cost savings and weight reduction. For many applications, particularly those involving AC current, the performance difference is minimal due to the skin effect phenomenon. The copper cladding carries most of the current, ensuring reliable electrical transmission while the aluminum core provides structural support and cost benefits.

Are there any installation considerations specific to copper clad aluminum

Yes, copper clad aluminum requires specific installation practices, particularly regarding terminations and connections. Approved connectors designed for copper clad aluminum must be used to prevent galvanic corrosion. Proper cleaning and preparation of conductor ends is essential, and torque specifications must be followed carefully to avoid damaging the composite structure while ensuring reliable electrical connections.

What applications are best suited for copper clad aluminum cables

Copper clad aluminum excels in telecommunications applications, including coaxial cables for cable TV and broadband internet, due to its excellent high-frequency performance. It's also well-suited for power transmission and distribution systems, overhead lines, and underground installations where cost-effectiveness and reliability are important. The material performs particularly well in AC applications where the skin effect maximizes the benefits of the copper cladding.