In today's rapidly evolving digital landscape, the demand for efficient and cost-effective data transmission solutions has never been higher. Network infrastructure professionals are increasingly turning to copper clad aluminum as a viable alternative to traditional copper wiring systems. This innovative conductor technology combines the excellent electrical properties of copper with the lightweight and economical advantages of aluminum, creating a solution that addresses many of the challenges faced in modern telecommunications and data center applications.

The telecommunications industry has witnessed significant transformations over the past decade, with bandwidth requirements increasing exponentially and installation costs becoming a critical factor in project planning. Copper clad aluminum emerges as a strategic solution that balances performance requirements with budget constraints, offering network designers and installers a practical approach to meeting contemporary connectivity demands while maintaining signal integrity and reliability standards.

Understanding Copper Clad Aluminum Technology

Construction and Manufacturing Process

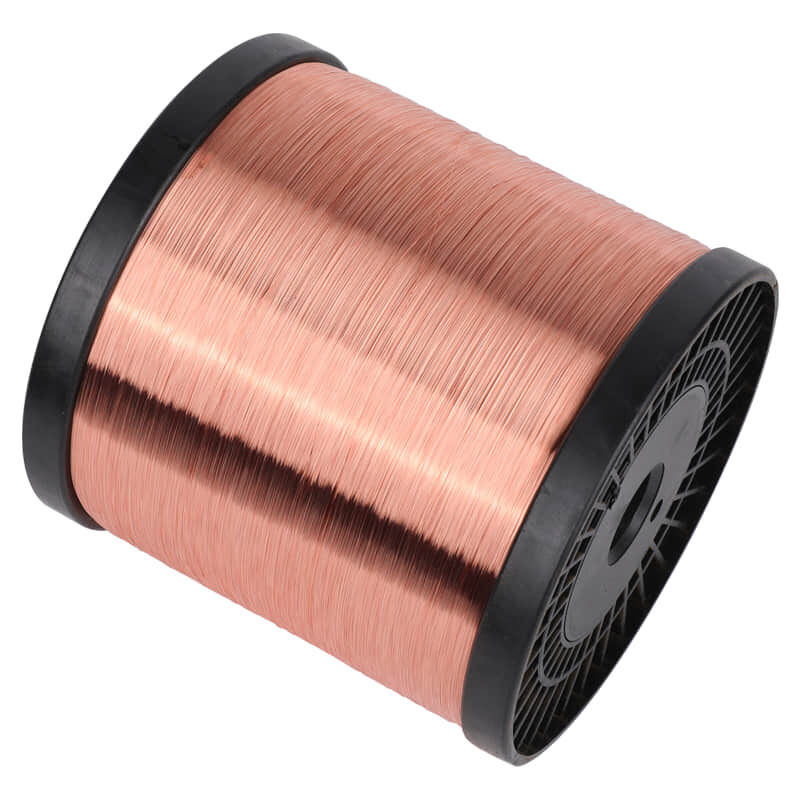

Copper clad aluminum represents a sophisticated manufacturing achievement where a thin layer of copper is metallurgically bonded to an aluminum core through advanced cladding processes. This bonding creates a permanent molecular connection between the two metals, ensuring that the copper layer cannot separate from the aluminum substrate under normal operating conditions. The manufacturing process typically involves drawing the aluminum core through dies while simultaneously applying the copper cladding, resulting in a uniform conductor with predictable electrical characteristics.

The precision required in producing high-quality copper clad aluminum involves careful control of temperature, pressure, and drawing speeds to achieve optimal bonding between the dissimilar metals. Modern manufacturing facilities utilize sophisticated quality control measures to ensure consistent cladding thickness and electrical performance throughout the production run. This attention to detail is crucial for maintaining the reliability standards expected in professional data transmission applications.

Material Properties and Characteristics

The unique properties of copper clad aluminum stem from the strategic combination of copper's superior conductivity with aluminum's favorable weight-to-strength ratio. The copper outer layer provides the primary conduction path for electrical signals, while the aluminum core contributes structural integrity and significantly reduces overall conductor weight. This combination results in a conductor that offers approximately 65% of the conductivity of solid copper while weighing substantially less.

Temperature stability is another notable characteristic of copper clad aluminum, as the thermal expansion coefficients of both metals are well-matched when properly bonded. This thermal compatibility reduces stress-related failures and maintains consistent electrical performance across varying environmental conditions. The material also demonstrates excellent resistance to corrosion when properly designed and installed, particularly in controlled indoor environments typical of data center and telecommunications applications.

Cost-Effectiveness and Economic Advantages

Material Cost Savings

One of the most compelling benefits of implementing copper clad aluminum in data transmission applications is the significant cost reduction compared to solid copper alternatives. With copper prices subject to market volatility and generally trending upward over time, aluminum-based solutions provide budget predictability and immediate material cost savings. These savings can be particularly substantial in large-scale installations where thousands of feet of conductor are required.

The cost advantages extend beyond the initial material purchase, as the reduced weight of copper clad aluminum can lead to lower shipping costs and reduced handling expenses during installation. Additionally, the improved availability of aluminum compared to copper can help avoid project delays caused by material shortages, providing indirect cost benefits through improved project scheduling and completion times.

Installation and Labor Efficiency

The lightweight nature of copper clad aluminum translates directly into reduced installation labor costs and improved installer productivity. Technicians can handle longer cable runs without fatigue, reducing the number of workers required for large installations. This weight advantage is particularly beneficial in overhead installations, ceiling-mounted cable trays, and situations where cables must be pulled through conduit or cable management systems.

The reduced physical stress on supporting infrastructure is another economic advantage, as lighter cables require less robust mounting hardware and support structures. This can result in savings on installation accessories, reduced structural modifications, and simplified cable management system designs. The cumulative effect of these factors often results in total project cost reductions that exceed the initial material savings alone.

Performance Benefits in Data Applications

Signal Transmission Quality

Despite being a composite conductor, copper clad aluminum delivers excellent signal transmission performance suitable for demanding data communication applications. The copper outer layer handles the majority of high-frequency signal transmission due to the skin effect, where alternating current tends to flow primarily in the outer conductor surface. This phenomenon makes the copper cladding highly effective for maintaining signal quality in data transmission scenarios.

The uniform conductor geometry achievable with modern copper clad aluminum manufacturing processes contributes to consistent impedance characteristics along the cable length. This impedance consistency is crucial for maintaining signal integrity in high-speed digital applications, reducing reflections and ensuring reliable data transmission. Properly designed copper clad aluminum cables can meet or exceed the performance requirements for many standard data transmission protocols.

Bandwidth and Frequency Response

Modern copper clad aluminum conductors demonstrate excellent performance across the frequency ranges commonly used in data transmission applications. The skin depth of electrical signals at typical data frequencies ensures that most of the current flows through the copper cladding layer, maximizing the utilization of copper's superior conductivity properties. This results in transmission characteristics that closely approximate those of solid copper conductors for many practical applications.

The frequency response characteristics of copper clad aluminum make it particularly suitable for applications such as Ethernet networking, cable television distribution, and other broadband communication systems. Careful attention to cable design parameters, including insulation materials and conductor geometry, allows copper clad aluminum cables to achieve performance levels suitable for high-speed data transmission requirements while maintaining the cost and weight advantages of the composite conductor technology.

Installation and Compatibility Considerations

Connector and Termination Compatibility

Successful implementation of copper clad aluminum in data transmission systems requires careful attention to connector selection and termination techniques. The presence of both copper and aluminum in the conductor creates unique considerations for establishing reliable electrical connections. Standard copper termination hardware can typically be used with copper clad aluminum, provided that proper techniques are employed to ensure good electrical contact with the copper cladding.

Professional installers must be trained in the specific techniques required for terminating copper clad aluminum conductors to prevent issues such as galvanic corrosion or poor electrical contact. This includes understanding the appropriate tools, connector types, and installation procedures that ensure long-term reliability. Many manufacturers provide detailed installation guidelines and compatible connector recommendations to support successful field implementation.

Environmental and Application Suitability

The environmental conditions and specific application requirements play crucial roles in determining the suitability of copper clad aluminum for particular installations. Indoor environments with controlled temperature and humidity conditions are generally ideal for copper clad aluminum applications, as they minimize the potential for corrosion and ensure stable performance over time. Data centers, office buildings, and telecommunications facilities typically provide the stable environmental conditions that maximize the benefits of this conductor technology.

Consideration must also be given to the specific electrical requirements of the intended application, including current carrying capacity, voltage drop limitations, and electromagnetic compatibility requirements. While copper clad aluminum offers excellent performance for many data transmission applications, engineers should verify that the selected conductor meets all relevant electrical and performance specifications for the specific system being designed.

Long-term Reliability and Maintenance

Durability and Service Life

The long-term reliability of copper clad aluminum in data transmission applications depends on several factors, including installation quality, environmental conditions, and system design considerations. When properly installed and maintained, copper clad aluminum systems can provide decades of reliable service comparable to traditional copper installations. The metallurgical bond between the copper and aluminum layers is designed to withstand the thermal cycling and mechanical stresses typically encountered in building and data center environments.

Regular inspection and maintenance protocols should be established to monitor the condition of copper clad aluminum installations over time. This includes checking terminations for signs of corrosion or loosening, monitoring system performance parameters, and addressing any environmental changes that might affect conductor performance. Proactive maintenance approaches help ensure that the cost and performance benefits of copper clad aluminum are realized throughout the system's operational life.

Troubleshooting and System Optimization

Effective troubleshooting of copper clad aluminum data transmission systems requires understanding of the unique characteristics of this conductor technology. Test equipment and procedures used for traditional copper systems are generally applicable to copper clad aluminum installations, though technicians should be aware of the specific electrical properties and potential failure modes associated with composite conductors.

System optimization techniques for copper clad aluminum installations focus on maximizing the utilization of the copper cladding for signal transmission while ensuring proper load distribution and thermal management. This may involve adjustments to termination techniques, connector selection, or environmental controls to optimize system performance and reliability over the long term.

FAQ

How does the electrical performance of copper clad aluminum compare to solid copper in data transmission applications

Copper clad aluminum typically provides approximately 65% of the conductivity of solid copper, which is sufficient for most data transmission applications due to the skin effect phenomenon. At the high frequencies used in data communications, electrical current flows primarily in the outer conductor surface, making the copper cladding highly effective for signal transmission. Properly designed copper clad aluminum cables can meet performance specifications for Ethernet, broadband, and other data communication protocols while offering significant cost and weight advantages.

What special installation considerations are required for copper clad aluminum conductors

Installing copper clad aluminum requires attention to proper termination techniques to ensure reliable electrical connections and prevent galvanic corrosion. Installers should use compatible connectors and follow manufacturer guidelines for termination procedures. The lighter weight of copper clad aluminum can simplify installation but requires proper training to achieve optimal results. Environmental considerations such as moisture control and temperature stability should also be addressed to maximize system reliability and performance.

Is copper clad aluminum suitable for high-speed data transmission and critical applications

Yes, copper clad aluminum can be suitable for high-speed data transmission when properly designed and installed. The copper outer layer handles high-frequency signals effectively due to skin effect, allowing copper clad aluminum cables to meet specifications for many demanding applications. However, critical applications should be evaluated on a case-by-case basis to ensure that all performance requirements are met, including considerations for current carrying capacity, voltage drop, and electromagnetic compatibility.

What are the long-term cost benefits of choosing copper clad aluminum over traditional copper conductors

The long-term cost benefits of copper clad aluminum include initial material cost savings of 20-40% compared to solid copper, reduced shipping and handling costs due to lighter weight, and potential labor savings during installation. Additionally, the price stability of aluminum compared to copper provides better budget predictability for large projects. When properly installed and maintained, copper clad aluminum systems can provide comparable service life to copper installations, making the total cost of ownership significantly lower than traditional copper solutions.

Table of Contents

- Understanding Copper Clad Aluminum Technology

- Cost-Effectiveness and Economic Advantages

- Performance Benefits in Data Applications

- Installation and Compatibility Considerations

- Long-term Reliability and Maintenance

-

FAQ

- How does the electrical performance of copper clad aluminum compare to solid copper in data transmission applications

- What special installation considerations are required for copper clad aluminum conductors

- Is copper clad aluminum suitable for high-speed data transmission and critical applications

- What are the long-term cost benefits of choosing copper clad aluminum over traditional copper conductors