Signal transmission efficiency remains a critical factor in modern telecommunications and electrical systems, where the choice of conductor material directly impacts performance, cost, and reliability. CCS Wire has emerged as an innovative solution that combines the electrical conductivity of copper with the mechanical strength of steel, offering unique advantages for various transmission applications. This composite conductor technology addresses the growing demands for efficient signal transmission while maintaining economic viability in large-scale installations. Understanding how CCS Wire enhances transmission efficiency requires examining its fundamental properties, construction methods, and real-world performance characteristics across different frequency ranges and environmental conditions.

Understanding CCS Wire Construction and Properties

Core Material Composition

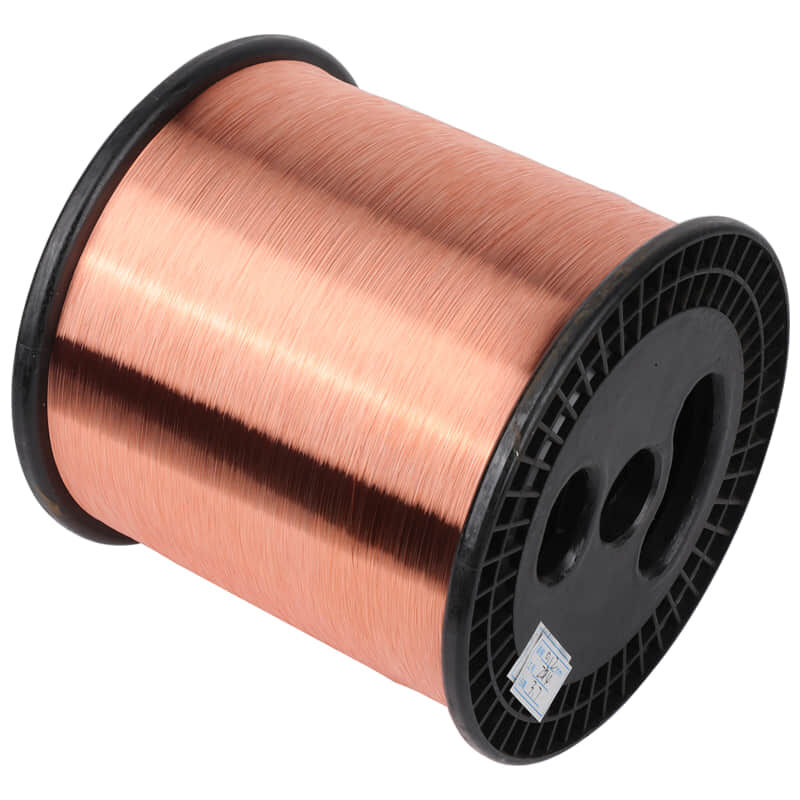

The fundamental structure of CCS Wire consists of a steel core surrounded by a copper cladding layer, creating a bi-metallic conductor that leverages the beneficial properties of both materials. The steel core provides mechanical strength and tensile durability, while the copper cladding ensures excellent electrical conductivity for signal transmission. Manufacturing processes typically involve either electroplating or continuous casting methods to achieve uniform copper coverage over the steel substrate. The thickness ratio between copper and steel layers can be customized based on specific application requirements, with typical copper percentages ranging from 10% to 40% of the total cross-sectional area. This construction method allows CCS Wire to maintain superior conductivity characteristics while significantly reducing material costs compared to solid copper conductors.

Electrical Characteristics and Performance

The electrical properties of CCS Wire demonstrate remarkable performance advantages in signal transmission applications, particularly in high-frequency environments where skin effect becomes prominent. At higher frequencies, electrical current tends to flow primarily through the outer surface of conductors, making the copper cladding the primary current-carrying path while the steel core provides structural support. This phenomenon allows CCS Wire to achieve conductivity levels approaching those of solid copper conductors at radio frequencies, while maintaining cost advantages through reduced copper content. The impedance characteristics remain stable across varying environmental conditions, ensuring consistent signal quality and minimal transmission losses in telecommunications systems.

Signal Transmission Efficiency Mechanisms

Skin Effect Optimization

The skin effect phenomenon plays a crucial role in how CCS Wire achieves superior signal transmission efficiency at radio frequencies. As frequency increases, electromagnetic fields penetrate only a limited depth into conductive materials, concentrating current flow near the surface. This characteristic makes the copper cladding layer the primary conduction path for high-frequency signals, while the steel core contributes minimal electrical resistance. The optimized copper thickness in CCS Wire is specifically designed to accommodate the skin depth requirements across various frequency ranges, ensuring maximum efficiency without unnecessary material costs. Engineering calculations demonstrate that properly designed CCS Wire can achieve over 95% of solid copper performance in many RF applications.

Impedance Control and Matching

Maintaining consistent characteristic impedance throughout transmission systems is essential for minimizing signal reflections and maximizing power transfer efficiency. CCS Wire offers excellent impedance stability due to its uniform construction and predictable electrical properties across temperature variations and mechanical stress conditions. The bi-metallic structure provides inherent immunity to oxidation-related impedance changes that can affect other conductor types over time. Manufacturing processes ensure precise dimensional control, resulting in consistent impedance characteristics that meet stringent telecommunications standards. This stability translates directly into improved signal transmission efficiency and reduced system maintenance requirements in critical communication infrastructure.

Performance Benefits in Telecommunications Applications

Cost-Effectiveness and Material Optimization

The economic advantages of CCS Wire extend beyond initial material costs to encompass installation, maintenance, and lifecycle considerations that impact overall system efficiency. By utilizing steel as the core material, CCS Wire achieves significant weight reduction compared to solid copper conductors of equivalent current-carrying capacity, reducing installation costs and structural requirements. The copper cladding provides long-term corrosion resistance and electrical stability, eliminating the need for frequent conductor replacements in harsh environmental conditions. Material optimization studies indicate that CCS Wire can reduce conductor costs by 30-50% while maintaining comparable electrical performance in many applications. This cost-effectiveness enables broader deployment of high-quality transmission systems and improved network coverage.

Mechanical Strength and Durability

The steel core construction of CCS Wire provides exceptional tensile strength and mechanical durability that directly contributes to signal transmission reliability and system longevity. Higher tensile strength allows for longer span lengths in overhead installations, reducing the number of support structures required and minimizing signal discontinuities. The composite structure resists stretching and deformation under thermal cycling and mechanical stress, maintaining consistent electrical properties throughout the service life. Environmental testing demonstrates that CCS Wire maintains stable transmission characteristics under extreme temperature variations, wind loading, and ice accumulation conditions. This mechanical robustness translates into reduced maintenance requirements and improved system availability for critical communication networks.

Frequency Response and Signal Quality

High-Frequency Performance Characteristics

The frequency response characteristics of CCS Wire demonstrate excellent performance across the radio frequency spectrum, making it particularly suitable for broadband communication systems and antenna applications. Laboratory measurements show that CCS Wire maintains low insertion loss and minimal phase distortion across frequency ranges from DC to several gigahertz, depending on the specific construction parameters. The copper cladding thickness can be optimized for specific frequency bands, ensuring maximum efficiency for targeted applications such as cellular communications, broadcast systems, or satellite links. Signal quality measurements consistently show that CCS Wire produces comparable results to solid copper conductors in terms of signal-to-noise ratio and harmonic distortion characteristics.

Attenuation and Loss Characteristics

Signal attenuation in CCS Wire systems remains consistently low due to the optimized conductor geometry and material properties that minimize both resistive and dielectric losses. The smooth copper surface provides excellent current flow characteristics, reducing surface roughness losses that can degrade high-frequency performance. Comparative testing reveals that CCS Wire exhibits attenuation characteristics within 5-10% of equivalent solid copper conductors across most practical frequency ranges. Environmental factors such as moisture, temperature, and contamination have minimal impact on the electrical performance due to the corrosion-resistant copper cladding. These low-loss characteristics translate directly into improved signal transmission efficiency and extended communication range capabilities.

Installation and System Integration

Compatibility and Connection Methods

The integration of CCS Wire into existing transmission systems requires careful consideration of connection methods and compatibility with standard termination hardware. Standard compression connectors, crimping tools, and soldering techniques can be adapted for CCS Wire applications, though specific procedures may be required to ensure optimal electrical contact with the copper cladding. Connection reliability studies demonstrate that properly installed CCS Wire terminations maintain stable contact resistance over extended periods, contributing to overall system efficiency. Industry standards organizations have developed specific guidelines for CCS Wire installation practices, ensuring consistent performance across different applications and installation environments. Training programs for installation technicians emphasize the unique characteristics of CCS Wire and proper handling techniques.

System Design Considerations

Effective system design with CCS Wire requires understanding the specific electrical and mechanical characteristics that differentiate it from traditional conductor materials. Design engineers must consider factors such as thermal expansion coefficients, current-carrying capacity ratings, and impedance matching requirements when specifying CCS Wire for transmission applications. Computer modeling and simulation tools have been developed to predict CCS Wire performance in complex system configurations, enabling optimized designs that maximize efficiency while minimizing costs. Field experience demonstrates that properly designed CCS Wire systems achieve performance levels comparable to traditional copper systems while providing significant economic and practical advantages. System integration guidelines help ensure that CCS Wire installations meet or exceed performance specifications.

Environmental Impact and Sustainability

Resource Conservation Benefits

The environmental benefits of CCS Wire extend beyond immediate cost savings to encompass broader sustainability considerations related to copper conservation and resource utilization. By reducing copper content by 60-90% compared to solid copper conductors, CCS Wire helps conserve this valuable natural resource while maintaining equivalent electrical performance in many applications. The steel core component can be sourced from recycled materials, further reducing the environmental impact of conductor manufacturing. Lifecycle assessments indicate that CCS Wire systems produce lower overall environmental impact when considering mining, processing, transportation, and end-of-life recycling factors. These sustainability advantages align with growing industry emphasis on environmentally responsible infrastructure development.

Recycling and End-of-Life Management

The bi-metallic construction of CCS Wire presents both opportunities and challenges for end-of-life recycling and material recovery. Specialized separation processes can recover both copper and steel components for reuse in new products, though the recycling infrastructure for CCS Wire is still developing in many regions. Industry initiatives are working to establish standardized recycling procedures and collection networks to maximize material recovery rates. Economic analysis suggests that the value of recovered materials can offset a significant portion of recycling costs, making CCS Wire recycling economically viable in many markets. Future developments in recycling technology may further improve the sustainability profile of CCS Wire systems.

FAQ

What makes CCS Wire more efficient than traditional copper wire for signal transmission

CCS Wire achieves comparable signal transmission efficiency to solid copper conductors through its optimized bi-metallic construction, where the copper cladding handles electrical conduction while the steel core provides mechanical strength. At radio frequencies where skin effect dominates current flow, the copper surface layer carries the signal effectively, making the interior steel core minimally impactful on electrical performance. This design allows CCS Wire to maintain over 95% of solid copper performance in many RF applications while reducing material costs by 30-50%. The consistent impedance characteristics and low attenuation properties ensure reliable signal quality across various frequency ranges and environmental conditions.

How does the skin effect benefit CCS Wire performance at higher frequencies

The skin effect phenomenon causes electrical current to concentrate near the conductor surface at higher frequencies, which perfectly complements the CCS Wire construction with its copper cladding layer. As frequency increases, current penetration depth decreases, making the outer copper layer the primary conduction path while the steel core provides structural support without significantly affecting electrical performance. This natural characteristic allows CCS Wire to achieve electrical performance nearly identical to solid copper at radio frequencies, since the interior steel material becomes electrically inactive. The copper cladding thickness is specifically engineered to accommodate skin depths across targeted frequency ranges, optimizing both performance and material efficiency.

Can CCS Wire handle the same current loads as equivalent solid copper conductors

CCS Wire current-carrying capacity depends on the copper cladding thickness and overall conductor geometry, typically achieving 70-85% of equivalent solid copper conductor ratings for continuous current applications. The bi-metallic construction creates some thermal considerations due to different expansion coefficients between copper and steel, requiring careful thermal design in high-current applications. However, for many signal transmission applications where current levels are relatively low, CCS Wire performs comparably to solid copper while providing superior mechanical strength and cost advantages. Proper derating calculations and thermal analysis ensure that CCS Wire installations operate within safe temperature limits while maintaining signal integrity and system reliability.

What are the long-term reliability considerations for CCS Wire installations

Long-term reliability of CCS Wire systems depends primarily on the quality of the copper cladding and the effectiveness of corrosion protection measures at connection points and terminations. The copper surface provides excellent corrosion resistance under normal environmental conditions, maintaining stable electrical characteristics over decades of service. However, mechanical damage to the cladding layer can expose the steel core to corrosion, potentially affecting performance over time. Regular inspection and maintenance protocols help identify potential issues before they impact system performance, while proper installation techniques and high-quality connection hardware ensure reliable long-term operation. Field experience with CCS Wire installations spanning over 20 years demonstrates satisfactory performance when properly installed and maintained.

Table of Contents

- Understanding CCS Wire Construction and Properties

- Signal Transmission Efficiency Mechanisms

- Performance Benefits in Telecommunications Applications

- Frequency Response and Signal Quality

- Installation and System Integration

- Environmental Impact and Sustainability

-

FAQ

- What makes CCS Wire more efficient than traditional copper wire for signal transmission

- How does the skin effect benefit CCS Wire performance at higher frequencies

- Can CCS Wire handle the same current loads as equivalent solid copper conductors

- What are the long-term reliability considerations for CCS Wire installations