The electrical industry demands reliable, safe, and high-performance wiring solutions that meet stringent certification standards. CCC Wire has emerged as a preferred choice for professionals seeking compliance with Chinese Compulsory Certification requirements while delivering exceptional conductivity and durability. This specialized copper-clad copper conductor combines the cost-effectiveness of aluminum with the superior electrical properties of pure copper, making it an ideal solution for various industrial and commercial applications. Understanding the comprehensive benefits of CCC Wire enables engineers, contractors, and facility managers to make informed decisions that enhance both performance and regulatory compliance in their electrical installations.

Understanding CCC Wire Technology and Construction

Advanced Copper-Clad Copper Design

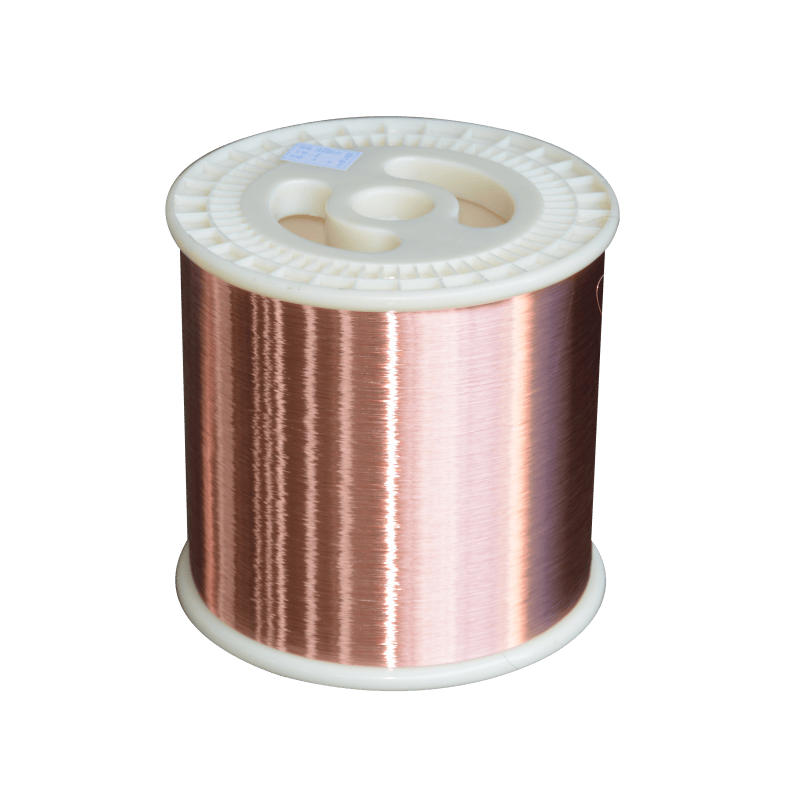

CCC Wire represents a sophisticated approach to electrical conductor manufacturing, utilizing a unique copper-clad copper construction that maximizes performance while optimizing material costs. The core structure consists of an aluminum or steel core completely surrounded by a seamless copper layer, creating a conductor that exhibits superior electrical characteristics compared to traditional alternatives. This innovative design ensures that electrical current flows primarily through the copper cladding, providing the excellent conductivity properties that electrical systems require. The manufacturing process involves precise metallurgical bonding techniques that create a permanent, corrosion-resistant interface between the core and copper cladding.

The engineering behind CCC Wire involves careful consideration of thermal expansion coefficients, mechanical stress distribution, and electrical impedance characteristics. Modern production facilities utilize advanced drawing and cladding processes that maintain consistent copper thickness throughout the wire length, ensuring uniform electrical properties across the entire conductor. This consistency is crucial for maintaining stable electrical performance in critical applications where voltage drops or impedance variations could compromise system functionality. The result is a conductor that delivers reliable performance while meeting strict manufacturing tolerances required for certified installations.

Material Properties and Performance Characteristics

The unique material composition of CCC Wire provides several distinct advantages over conventional copper or aluminum conductors. The copper cladding offers excellent corrosion resistance, protecting the core material from environmental factors that could degrade conductor performance over time. This protective barrier is particularly important in installations exposed to moisture, chemical vapors, or temperature fluctuations that might otherwise compromise conductor integrity. The electrical properties of CCC Wire closely match those of solid copper conductors, with minimal resistance differences that make it suitable for applications requiring high current-carrying capacity.

Mechanical properties of CCC Wire include excellent flexibility and bend radius characteristics, making installation easier and reducing the risk of conductor damage during handling. The copper cladding provides superior termination properties, allowing for reliable connections using standard copper termination methods and hardware. Temperature coefficients remain stable across wide operating ranges, ensuring consistent performance in environments subject to thermal cycling. These combined properties make CCC Wire an excellent choice for applications where both electrical performance and mechanical reliability are essential requirements.

Certification Standards and Regulatory Compliance

Chinese Compulsory Certification Requirements

The CCC certification system represents one of the most comprehensive electrical product safety standards globally, requiring rigorous testing and documentation to ensure product safety and performance. CCC Wire manufacturers must demonstrate compliance with multiple technical standards covering electrical performance, fire resistance, environmental impact, and mechanical durability. The certification process involves extensive factory inspections, product testing by accredited laboratories, and ongoing quality assurance programs that maintain consistent product standards. This comprehensive approach ensures that CCC Wire products meet the highest safety and performance requirements for electrical installations.

Compliance with CCC standards provides several important benefits for electrical contractors and facility owners. The certification guarantees that the wire meets specific technical parameters for current-carrying capacity, insulation properties, and fire resistance characteristics. Regular audits and testing ensure that production quality remains consistent, reducing the risk of product failures or safety issues. The CCC Wire certification also facilitates acceptance by regulatory authorities and inspection agencies, streamlining the approval process for new installations and renovations.

International Standards Alignment

CCC Wire specifications align with numerous international electrical standards, making these products suitable for use in global markets and multinational projects. The certification requirements incorporate elements from IEC, IEEE, and other recognized standards organizations, ensuring compatibility with international design practices and installation requirements. This alignment is particularly valuable for companies operating in multiple jurisdictions, as it reduces the complexity of specifying and procuring electrical materials for different markets. The comprehensive testing requirements of CCC certification often exceed those of regional standards, providing additional assurance of product quality and reliability.

The international recognition of CCC standards has grown significantly as global supply chains become more integrated and quality requirements become more stringent. Many international projects now specifically require CCC-certified materials as a baseline quality standard, recognizing the thorough testing and quality assurance processes involved in the certification. This acceptance has made CCC Wire an increasingly attractive option for contractors and engineers working on projects with strict quality requirements or those seeking to establish consistent material standards across multiple installations.

Installation Advantages and Performance Benefits

Enhanced Electrical Performance

The electrical performance characteristics of CCC Wire make it particularly well-suited for demanding applications where consistent power delivery and minimal losses are critical requirements. The copper cladding provides excellent conductivity properties that closely match those of solid copper conductors, while the engineered core structure optimizes the conductor's current-carrying capacity relative to its weight and cost. This combination results in improved system efficiency and reduced energy losses compared to alternative conductor materials, making CCC Wire an economically attractive choice for high-usage applications.

Voltage regulation and power quality benefits are significant advantages of CCC Wire installations. The consistent electrical properties and low impedance characteristics help maintain stable voltage levels across distribution systems, reducing the risk of equipment malfunction or premature failure due to voltage variations. The superior current-carrying capacity allows for more compact installations while maintaining adequate capacity margins, enabling more efficient use of available space and reducing installation costs. These performance advantages are particularly noticeable in applications with high current demands or sensitive electronic equipment requiring stable power supplies.

Installation Efficiency and Cost Benefits

The physical properties of CCC Wire contribute significantly to installation efficiency and overall project cost savings. The lightweight construction reduces handling difficulties and transportation costs, while maintaining the mechanical strength necessary for secure installations. The flexibility characteristics of CCC Wire simplify routing through conduits, cable trays, and tight spaces, reducing installation time and labor costs. Standard termination methods and hardware can be used with CCC Wire, eliminating the need for special tools or training that might be required with alternative conductor materials.

Long-term maintenance advantages of CCC Wire installations include excellent corrosion resistance and stable electrical properties that reduce the likelihood of premature replacement or repair requirements. The reliable performance characteristics minimize system downtime and maintenance costs, contributing to lower total cost of ownership over the installation's operational life. The durability of CCC Wire connections and terminations reduces the frequency of inspection and maintenance activities, allowing facility maintenance teams to focus resources on other critical systems and equipment.

Applications and Industry Use Cases

Commercial and Industrial Installations

CCC Wire finds extensive application in commercial and industrial electrical systems where reliability, efficiency, and cost-effectiveness are paramount considerations. Large office buildings, manufacturing facilities, and data centers benefit from the superior electrical performance and installation advantages that CCC Wire provides. The certification requirements ensure that these installations meet strict safety standards while delivering the performance characteristics needed for modern electrical systems. The combination of excellent conductivity and cost optimization makes CCC Wire particularly attractive for projects with substantial wire requirements.

Manufacturing environments present unique challenges for electrical installations, including exposure to harsh operating conditions, high electrical loads, and strict reliability requirements. CCC Wire addresses these challenges through its robust construction and consistent performance characteristics. The corrosion resistance properties are particularly valuable in industrial settings where chemical exposure or high humidity might compromise other conductor materials. The reliable electrical performance helps maintain consistent operation of critical production equipment, reducing the risk of costly downtime or product quality issues.

Infrastructure and Utility Applications

Utility and infrastructure applications represent significant growth areas for CCC Wire usage, as these installations require conductors that can deliver reliable performance over extended service lives. Power distribution systems, telecommunications infrastructure, and renewable energy installations benefit from the superior performance characteristics and certification standards that CCC Wire provides. The combination of electrical performance and cost optimization makes CCC Wire an attractive alternative to traditional copper conductors in applications where material costs represent a significant portion of total project expenses.

Smart grid and modern infrastructure projects increasingly specify CCC Wire for its consistent performance characteristics and compliance with international standards. The reliable electrical properties support advanced monitoring and control systems that require stable power delivery and minimal electrical interference. The certification standards provide additional assurance that these critical infrastructure installations will meet performance requirements throughout their designed service life, supporting the reliability and efficiency goals of modern electrical systems.

Quality Assurance and Testing Protocols

Manufacturing Quality Control

CCC Wire manufacturing involves comprehensive quality control processes that ensure consistent product performance and compliance with certification requirements. Advanced testing equipment monitors electrical properties, mechanical characteristics, and dimensional tolerances throughout the production process. Statistical process control methods track key performance parameters and identify potential quality issues before they can affect finished products. This proactive approach to quality management helps maintain the high standards required for CCC certification while minimizing production variations that could impact installation performance.

Raw material qualification and supplier management programs ensure that all components used in CCC Wire production meet specified quality standards. Incoming inspection procedures verify that copper, insulation materials, and other components conform to design requirements before they enter the production process. Regular supplier audits and performance reviews maintain consistent material quality and help identify opportunities for continuous improvement. These comprehensive quality assurance programs provide the foundation for reliable CCC Wire performance in demanding applications.

Performance Validation and Testing

Extensive testing protocols validate CCC Wire performance across a wide range of operating conditions and application requirements. Electrical testing includes conductivity measurements, insulation resistance verification, and high-voltage breakdown testing to ensure that products meet or exceed specification requirements. Mechanical testing evaluates bend radius characteristics, tensile strength, and fatigue resistance to confirm that the wire can withstand installation stresses and operational loads. Environmental testing exposes samples to temperature cycling, humidity exposure, and chemical resistance challenges that simulate real-world operating conditions.

Third-party testing and certification provide independent verification of CCC Wire performance and compliance with applicable standards. Accredited testing laboratories conduct comprehensive evaluations using standardized test methods that ensure consistent and repeatable results. The testing data supports the certification process and provides documentation that can be used for regulatory approvals and project specifications. Regular re-testing and surveillance activities maintain certification validity and ensure that production quality remains consistent over time.

Economic Benefits and Cost Analysis

Initial Cost Considerations

The economic advantages of CCC Wire become apparent when considering both initial material costs and long-term operational benefits. While the upfront cost may be comparable to or slightly higher than some alternative conductors, the superior performance characteristics and durability of CCC Wire provide significant value over the installation's operational life. The certification requirements ensure consistent quality that reduces the risk of premature failures or performance issues that could result in costly repairs or replacements. This reliability translates into lower total cost of ownership and improved return on investment for electrical infrastructure projects.

Installation cost savings represent another important economic benefit of CCC Wire selection. The lightweight construction and excellent handling characteristics reduce labor requirements during installation, while the compatibility with standard termination methods eliminates the need for specialized tools or training. The reliable performance characteristics minimize the need for oversizing conductors or installing redundant systems, allowing for more efficient use of available space and resources. These installation advantages are particularly valuable in projects with tight schedules or limited access for construction activities.

Long-Term Value Proposition

The long-term economic benefits of CCC Wire installations extend well beyond initial cost considerations, encompassing reduced maintenance requirements, improved system efficiency, and extended service life. The excellent corrosion resistance and stable electrical properties minimize the likelihood of degradation or failure over time, reducing maintenance costs and system downtime. The superior conductivity characteristics help maintain system efficiency throughout the installation's operational life, reducing energy costs and improving overall system performance. These benefits accumulate over time, providing substantial economic value that often exceeds the initial material cost differences.

Energy efficiency benefits of CCC Wire installations contribute to ongoing operational cost savings through reduced losses and improved power quality. The low resistance characteristics minimize I²R losses in distribution systems, reducing energy consumption and associated costs. The stable electrical properties help maintain consistent voltage levels that improve the efficiency and reliability of connected equipment. These energy savings can be substantial in high-usage applications, providing a measurable return on investment that justifies the selection of CCC Wire for critical electrical installations.

FAQ

What makes CCC Wire different from standard copper wire

CCC Wire features a unique copper-clad copper construction that combines an aluminum or steel core with a seamless copper outer layer, providing the electrical performance of solid copper at a reduced cost. The Chinese Compulsory Certification ensures rigorous quality standards and performance verification that may exceed those of standard copper products. This construction method delivers excellent conductivity while optimizing material costs, making it particularly suitable for large installations where wire costs represent a significant portion of the total project budget.

How does CCC certification benefit electrical contractors and facility owners

CCC certification provides comprehensive quality assurance through rigorous testing, factory inspections, and ongoing quality monitoring programs. This certification ensures that CCC Wire meets strict performance standards for electrical properties, fire resistance, and mechanical durability. For contractors and facility owners, this means reduced risk of product failures, easier regulatory approvals, and confidence in long-term performance. The certification also facilitates acceptance by inspection agencies and helps streamline the project approval process.

Can CCC Wire be used with standard electrical installation methods and hardware

Yes, CCC Wire is designed to be compatible with standard copper installation methods, termination hardware, and connection practices. The copper cladding allows for reliable connections using conventional copper lugs, connectors, and splicing methods without requiring special tools or techniques. This compatibility simplifies installation procedures, reduces training requirements, and ensures that standard electrical practices can be followed throughout the installation process.

What are the primary applications where CCC Wire provides the greatest advantages

CCC Wire delivers maximum benefits in applications with substantial wire requirements, such as large commercial buildings, industrial facilities, data centers, and infrastructure projects. The cost optimization and performance characteristics make it particularly attractive for power distribution systems, lighting circuits, and applications requiring high current-carrying capacity. The certification standards and reliability characteristics also make CCC Wire well-suited for critical installations where consistent performance and regulatory compliance are essential requirements.