In today's rapidly evolving electrical infrastructure landscape, selecting the right conductor technology can make the difference between reliable power transmission and costly system failures. CCC Wire has emerged as a revolutionary solution that combines the best properties of copper and aluminum conductors, delivering exceptional performance for critical power applications. This advanced conductor technology offers superior electrical conductivity, enhanced mechanical strength, and cost-effective installation benefits that traditional single-metal conductors simply cannot match. As power demands continue to increase across industrial, commercial, and utility sectors, understanding the advantages of CCC Wire becomes essential for engineers, project managers, and electrical contractors seeking optimal performance solutions.

Understanding CCC Wire Technology and Construction

Copper Clad Copper Core Architecture

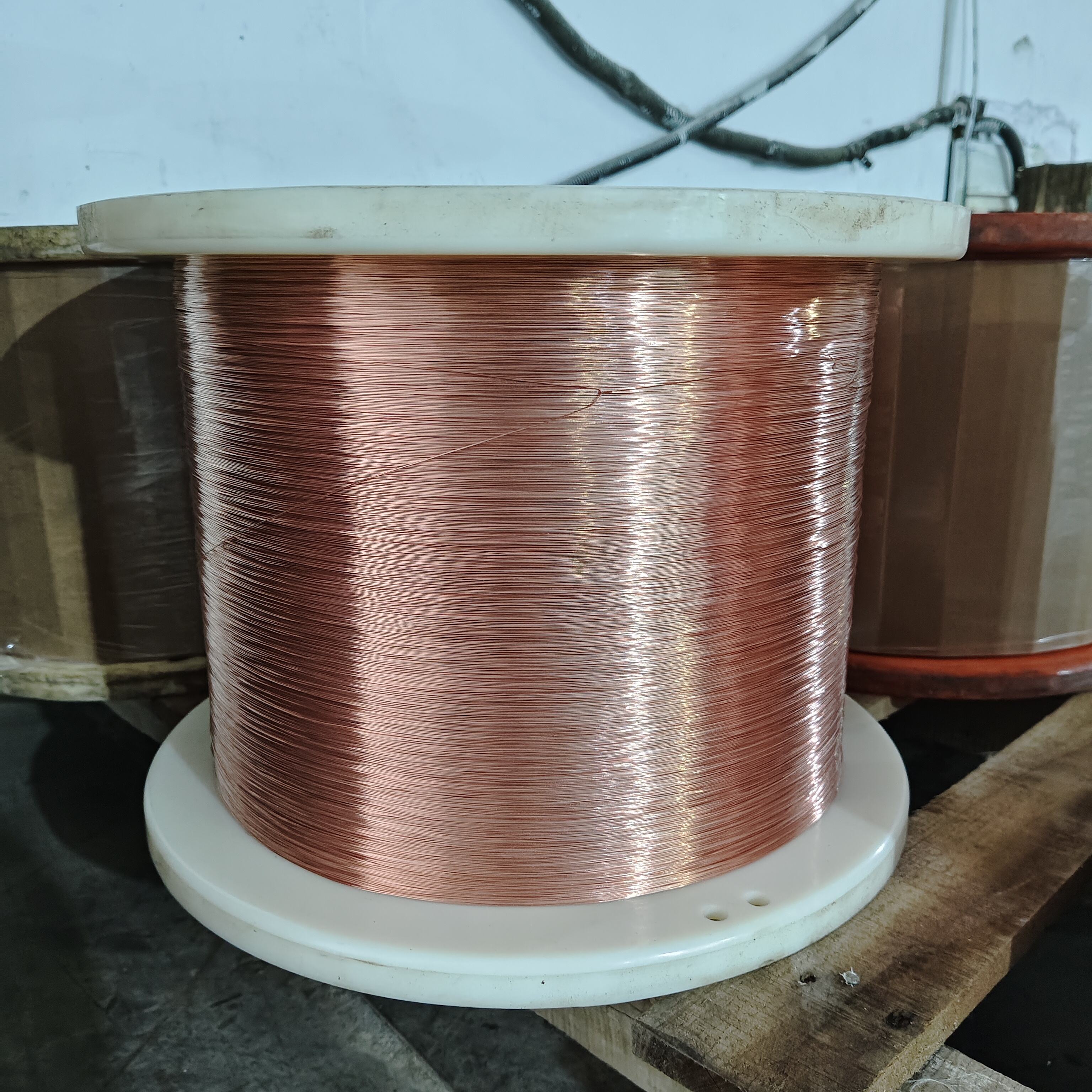

The fundamental design of CCC Wire centers on a sophisticated bi-metallic construction that maximizes the inherent benefits of both copper and aluminum materials. The conductor features a high-conductivity aluminum core that provides excellent current-carrying capacity while maintaining significantly reduced weight compared to solid copper alternatives. This aluminum core is precision-clad with a layer of high-purity copper, creating a seamless metallurgical bond that ensures optimal electrical performance and corrosion resistance. The copper cladding process involves advanced manufacturing techniques that guarantee uniform thickness and complete coverage across the entire conductor surface.

The metallurgical bonding between the copper cladding and aluminum core creates a conductor that exhibits superior electrical characteristics compared to traditional aluminum conductors. The copper outer layer provides enhanced surface conductivity, which is particularly important for high-frequency applications and helps minimize skin effect losses. This construction methodology ensures that CCC Wire maintains consistent performance across a wide range of operating conditions while offering the economic advantages of aluminum-based conductors. The precise engineering of the copper-to-aluminum ratio optimizes both electrical and mechanical properties for demanding power transmission applications.

Manufacturing Process and Quality Standards

The production of CCC Wire involves rigorous quality control measures and advanced manufacturing processes that ensure consistent performance characteristics across every batch. State-of-the-art cladding facilities utilize controlled atmosphere environments to prevent oxidation during the bonding process, resulting in superior metallurgical integrity. Temperature and pressure parameters are precisely monitored throughout the manufacturing cycle to achieve optimal copper-aluminum interface bonding. Multiple quality checkpoints verify dimensional accuracy, surface finish, and electrical properties before final product approval.

Comprehensive testing protocols validate the performance capabilities of each CCC Wire production run, including tensile strength measurements, conductivity verification, and thermal cycling assessments. These manufacturing standards ensure that every conductor meets or exceeds international specifications for power transmission applications. The quality assurance program encompasses raw material inspection, in-process monitoring, and final product validation to guarantee reliable field performance. Advanced metallurgical analysis techniques confirm the integrity of the copper-aluminum bond and verify long-term stability under operating conditions.

Electrical Performance Advantages

Superior Conductivity Characteristics

CCC Wire delivers exceptional electrical conductivity that approaches pure copper performance while maintaining the weight advantages of aluminum-core construction. The copper cladding provides a low-resistance current path that minimizes power losses and ensures efficient energy transmission across long distances. This enhanced conductivity translates directly to improved system efficiency and reduced operating costs for utilities and industrial facilities. The uniform copper surface also provides consistent electrical characteristics that remain stable throughout the conductor's service life.

Comparative testing demonstrates that CCC Wire exhibits lower DC resistance values than equivalent aluminum conductors while offering significantly better performance than copper-clad steel alternatives. The superior surface conductivity helps minimize alternating current losses, making this conductor technology particularly valuable for high-frequency and variable load applications. Temperature coefficient characteristics remain stable across operating ranges, ensuring predictable performance under varying environmental conditions. The excellent conductivity properties make CCC Wire an ideal choice for applications requiring maximum power transfer efficiency.

Thermal Management and Current Capacity

The thermal characteristics of CCC Wire provide significant advantages for high-current applications where heat dissipation becomes a critical design factor. The aluminum core offers excellent thermal conductivity that helps distribute heat uniformly throughout the conductor cross-section, preventing localized hot spots that can compromise system reliability. The copper cladding enhances surface heat transfer, allowing for more effective cooling under both natural and forced ventilation conditions. This superior thermal management capability enables higher current ratings compared to traditional conductor technologies.

Current-carrying capacity calculations for CCC Wire consistently demonstrate improved ampacity ratings compared to equivalent cross-sectional area aluminum conductors. The enhanced thermal properties allow for reduced conductor sizes in many applications while maintaining required current capacity, resulting in material cost savings and simplified installation procedures. Temperature rise characteristics remain within acceptable limits even under emergency overload conditions, providing additional safety margins for critical power systems. The combination of high conductivity and excellent thermal management makes CCC Wire particularly suitable for applications with demanding current requirements.

Mechanical Strength and Durability Benefits

Enhanced Tensile Strength Properties

The mechanical properties of CCC Wire provide significant advantages for overhead transmission lines and underground cable installations where mechanical stress resistance is paramount. The aluminum core contributes excellent tensile strength while maintaining flexibility for installation around obstacles and through conduit systems. The copper cladding adds surface durability and protection against mechanical damage during handling and installation procedures. This combination results in a conductor that can withstand high tension loads while maintaining electrical integrity throughout its service life.

Stress-strain testing reveals that CCC Wire exhibits superior elongation characteristics compared to traditional aluminum conductors, providing better resistance to fatigue failure under dynamic loading conditions. The metallurgical bond between copper and aluminum layers distributes mechanical stresses evenly, preventing delamination or separation under normal operating tensions. Wind loading calculations demonstrate improved performance for overhead applications where conductor sag and tension variations are critical design considerations. The enhanced mechanical properties enable longer span lengths and reduced support structure requirements in many installations.

Corrosion Resistance and Environmental Durability

Environmental durability represents one of the most significant advantages of CCC Wire technology, particularly in challenging atmospheric conditions where traditional aluminum conductors may experience accelerated degradation. The copper cladding provides exceptional corrosion resistance against salt spray, industrial pollutants, and acidic atmospheric conditions that commonly affect coastal and urban installations. This protective barrier prevents direct contact between the aluminum core and corrosive elements, significantly extending conductor service life in harsh environments.

Long-term exposure testing confirms that CCC Wire maintains stable electrical and mechanical properties even after extended periods in aggressive environmental conditions. The copper surface resists oxidation and maintains low contact resistance at connection points, reducing maintenance requirements and improving system reliability. Galvanic corrosion concerns are minimized through proper design of connection hardware and termination procedures. The superior environmental resistance makes CCC Wire an excellent choice for installations in coastal areas, industrial zones, and other challenging atmospheric conditions where conductor longevity is a primary concern.

Installation and Connection Advantages

Simplified Handling and Installation Procedures

The installation characteristics of CCC Wire offer significant advantages over traditional conductor options, particularly in terms of handling ease and installation flexibility. The reduced weight compared to solid copper conductors simplifies transportation and reduces installation labor requirements while maintaining superior electrical performance. Installation crews can handle longer conductor lengths without additional lifting equipment, improving installation efficiency and reducing project completion times. The flexibility of the aluminum core allows for easier routing through congested areas and around obstacles.

Bending radius requirements for CCC Wire are typically less restrictive than solid copper alternatives, allowing for tighter installation configurations without compromising conductor integrity. The copper surface provides excellent grip characteristics for pulling operations through conduit systems and underground duct banks. Installation damage resistance is enhanced compared to bare aluminum conductors, reducing the likelihood of surface nicks or scratches that could compromise long-term performance. These installation advantages translate to reduced labor costs and improved project schedules for electrical contractors and utility crews.

Connection Hardware and Termination Benefits

Connection procedures for CCC Wire are streamlined compared to aluminum conductor installations, as the copper surface eliminates many of the special preparation requirements associated with aluminum terminations. Standard copper connection hardware can be utilized without the need for specialized compounds or surface preparation procedures. The copper cladding provides excellent contact surface characteristics that ensure low-resistance connections throughout the system service life. Termination procedures follow established copper conductor practices, reducing training requirements and potential installation errors.

Joint resistance measurements consistently demonstrate stable, low-resistance connections that remain reliable under thermal cycling and mechanical stress conditions. The copper surface prevents oxidation at connection points, eliminating the need for periodic maintenance associated with aluminum conductor joints. Compression and mechanical connection hardware designed for copper applications provides optimal performance with CCC Wire installations. The simplified connection procedures reduce installation time and improve overall system reliability by minimizing potential points of failure in power transmission networks.

Economic Benefits and Cost Analysis

Material Cost Optimization

The economic advantages of CCC Wire become apparent when analyzing total project costs including material, installation, and long-term operating expenses. While the initial conductor cost may be higher than standard aluminum alternatives, the superior performance characteristics often allow for reduced cross-sectional areas to achieve equivalent current ratings. This size reduction translates to material savings in support structures, conduit systems, and installation hardware. The combination of aluminum core economics with copper performance provides an optimal balance between initial investment and operational benefits.

Life-cycle cost analysis consistently demonstrates favorable returns for CCC Wire installations when factoring in reduced maintenance requirements, improved system efficiency, and extended service life. The superior corrosion resistance eliminates premature replacement costs associated with environmental degradation of traditional conductors. Energy efficiency improvements from reduced resistance losses provide ongoing operational savings that accumulate over the conductor service life. Total cost of ownership calculations typically show positive returns within the first few years of operation for most applications.

Installation Cost Reduction Opportunities

Installation cost savings represent a significant economic advantage for CCC Wire projects, particularly in applications where labor costs constitute a major portion of total project expenses. The reduced weight facilitates faster installation procedures and may eliminate the need for specialized lifting equipment in some applications. Simplified connection procedures reduce installation time and minimize the potential for costly installation errors. The improved handling characteristics allow installation crews to work more efficiently while maintaining high quality standards.

Reduced conductor sizes enable the use of smaller conduit systems and support structures, providing additional cost savings in underground and overhead installations. The superior mechanical properties may allow for longer span lengths in overhead applications, reducing the number of support structures required. Project scheduling benefits from faster installation procedures and reduced complexity of connection operations. These installation advantages contribute to improved project profitability and shorter construction schedules for electrical contractors and project developers.

Applications and Industry Use Cases

Utility and Power Transmission Applications

CCC Wire technology has gained widespread acceptance in utility transmission and distribution networks where reliability and performance are paramount concerns. High-voltage transmission lines benefit from the superior conductivity and mechanical strength characteristics that enable longer spans and higher current ratings. Distribution feeders utilize CCC Wire for improved voltage regulation and reduced power losses in densely populated service areas. The environmental durability makes this conductor technology particularly valuable for coastal and industrial utility installations where traditional conductors may experience accelerated degradation.

Substation bus and switching applications leverage the excellent connection characteristics and stability of CCC Wire under fault current conditions. Underground transmission cables incorporating CCC Wire technology provide enhanced performance in urban environments where space constraints and environmental conditions challenge traditional conductor materials. Rural electrification projects benefit from the cost-effective performance and reduced maintenance requirements associated with this advanced conductor technology. The versatility of CCC Wire makes it suitable for both new construction and system upgrade applications across the utility industry.

Industrial and Commercial Power Systems

Industrial facilities with critical power requirements increasingly specify CCC Wire for main distribution feeders and equipment connections where system reliability directly impacts production capacity. Manufacturing plants benefit from the stable electrical characteristics and reduced maintenance requirements that minimize unplanned downtime and production interruptions. Data centers and telecommunications facilities utilize CCC Wire for power distribution systems where consistent performance and long-term reliability are essential for mission-critical operations.

Commercial building electrical systems incorporate CCC Wire technology for main service feeders and critical distribution circuits where space constraints and installation efficiency are important considerations. Hospital and healthcare facilities rely on the superior performance characteristics for emergency power systems and critical care equipment feeders. Educational institutions benefit from the long-term cost advantages and reduced maintenance requirements for campus electrical distribution networks. The broad applicability of CCC Wire technology makes it suitable for diverse commercial and industrial power system requirements.

FAQ

What makes CCC Wire different from traditional aluminum or copper conductors

CCC Wire features a unique bi-metallic construction with an aluminum core clad in high-purity copper, combining the weight advantages of aluminum with the superior electrical and corrosion resistance properties of copper. This construction provides better conductivity than standard aluminum while maintaining significantly lower weight than solid copper conductors. The metallurgical bonding between materials creates a stable, long-lasting conductor that outperforms traditional single-metal alternatives in most applications.

How does CCC Wire performance compare in terms of current carrying capacity

CCC Wire typically provides 15-20% higher current carrying capacity compared to equivalent size aluminum conductors due to improved thermal management and surface conductivity characteristics. The copper cladding enhances heat dissipation while the aluminum core provides excellent thermal conductivity throughout the conductor cross-section. This combination allows for higher ampacity ratings and may enable the use of smaller conductor sizes for many applications while maintaining required current capacity.

What are the installation requirements and connection procedures for CCC Wire

Installation procedures for CCC Wire follow standard copper conductor practices, eliminating the special surface preparation and compound requirements associated with aluminum installations. Standard copper connection hardware can be used without modification, and termination procedures are simplified compared to aluminum conductors. The copper surface provides excellent contact characteristics and eliminates oxidation concerns at connection points, resulting in reliable, low-maintenance joints throughout the system service life.

Is CCC Wire suitable for all environmental conditions and applications

CCC Wire demonstrates excellent performance across a wide range of environmental conditions, with particular advantages in corrosive atmospheres where the copper cladding provides superior protection compared to aluminum conductors. The technology is suitable for both overhead and underground applications, with proven performance in coastal, industrial, and urban environments. While CCC Wire can be used in most standard electrical applications, specific project requirements should always be evaluated to ensure optimal performance and cost-effectiveness for each installation.

Table of Contents

- Understanding CCC Wire Technology and Construction

- Electrical Performance Advantages

- Mechanical Strength and Durability Benefits

- Installation and Connection Advantages

- Economic Benefits and Cost Analysis

- Applications and Industry Use Cases

-

FAQ

- What makes CCC Wire different from traditional aluminum or copper conductors

- How does CCC Wire performance compare in terms of current carrying capacity

- What are the installation requirements and connection procedures for CCC Wire

- Is CCC Wire suitable for all environmental conditions and applications