Power distribution systems form the backbone of modern electrical infrastructure, requiring components that deliver exceptional performance over decades of service. When evaluating wire solutions for long-term applications, engineers and procurement specialists increasingly turn to CCC Wire as a proven alternative to traditional solid copper conductors. This advanced conductor technology combines the superior conductivity of copper with enhanced mechanical properties and cost-effectiveness, making it particularly attractive for large-scale power distribution projects.

The reliability of electrical conductors directly impacts system availability, maintenance costs, and operational safety across industrial facilities, commercial buildings, and utility networks. CCC Wire technology addresses critical performance requirements while offering significant advantages in terms of installation flexibility and long-term durability. Understanding the technical characteristics and real-world performance data helps decision-makers evaluate whether this conductor solution aligns with their specific power distribution requirements.

Understanding CCC Wire Construction and Technology

Core Design Principles

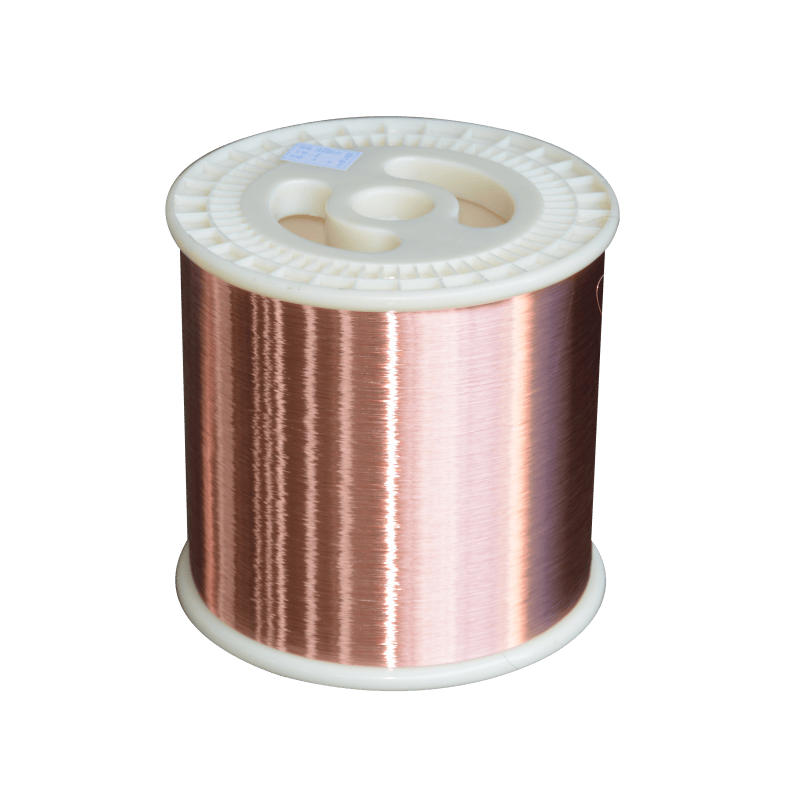

CCC Wire utilizes a sophisticated manufacturing process that creates a seamless bond between a high-conductivity copper outer layer and a steel or aluminum core. This composite structure leverages the electrical properties of copper while benefiting from the mechanical strength and weight advantages of the core material. The copper cladding thickness is precisely controlled to ensure optimal electrical performance while maintaining cost efficiency throughout the conductor's operational life.

The manufacturing process involves advanced metallurgical techniques that create a molecular bond between the copper cladding and core material. This eliminates the potential for delamination or separation that could compromise electrical integrity over time. The resulting conductor exhibits uniform electrical characteristics along its entire length, ensuring consistent performance in demanding power distribution applications.

Material Composition Advantages

The strategic use of materials in CCC Wire construction delivers multiple performance benefits compared to traditional conductors. The copper cladding provides excellent corrosion resistance and maintains stable electrical properties even in challenging environmental conditions. Meanwhile, the core material contributes to improved tensile strength and reduced weight, facilitating easier installation and reducing structural loading on support systems.

Quality control measures during manufacturing ensure that each conductor meets stringent specifications for cladding thickness, concentricity, and electrical properties. These controls are essential for achieving the long-term reliability that power distribution systems require. The consistent material properties across production batches enable reliable system design and predictable performance characteristics throughout the installation.

Electrical Performance Characteristics

Conductivity and Resistance Properties

The electrical performance of CCC Wire closely matches that of solid copper conductors in most power distribution applications. The copper cladding carries the majority of electrical current due to the skin effect at power frequencies, ensuring minimal impact on system efficiency. Resistance measurements demonstrate that properly designed CCC Wire maintains electrical characteristics within acceptable tolerance ranges for both AC and DC applications.

Temperature coefficient behavior of CCC Wire follows predictable patterns that align with standard electrical design practices. The conductor maintains stable resistance characteristics across operational temperature ranges, ensuring reliable performance in both indoor and outdoor installations. This thermal stability contributes to consistent voltage regulation and power quality throughout the distribution system.

Current Carrying Capacity

Ampacity ratings for CCC Wire are established through comprehensive testing that considers thermal, electrical, and mechanical factors. The conductor's current carrying capacity typically meets or exceeds that of equivalent solid copper conductors when properly applied in accordance with installation standards. Heat dissipation characteristics benefit from the composite construction, which can provide improved thermal management in certain installation configurations.

Short-circuit current handling capability represents another critical performance parameter for power distribution applications. CCC Wire demonstrates adequate fault current withstand capacity when properly sized for specific system requirements. The mechanical strength provided by the core material can offer advantages during fault conditions, reducing the risk of conductor damage or system failure.

Long-Term Reliability Factors

Environmental Durability

Environmental exposure testing reveals that CCC Wire maintains structural and electrical integrity under various atmospheric conditions. The copper cladding provides excellent protection against oxidation and corrosion, which are primary failure modes in electrical conductors. Accelerated aging tests demonstrate minimal degradation in electrical properties over extended exposure periods.

Moisture resistance and chemical compatibility testing show that CCC Wire performs well in industrial environments where traditional conductors might experience premature failure. The robust construction resists damage from common industrial chemicals and maintains electrical performance even in high-humidity conditions. This environmental resilience translates to reduced maintenance requirements and longer service life in challenging installations.

Mechanical Stress Performance

The composite construction of CCC Wire provides enhanced resistance to mechanical stresses that can occur during installation and operation. Tensile strength testing demonstrates superior performance compared to solid copper conductors of equivalent electrical rating. This mechanical advantage reduces the risk of conductor damage during pulling operations and provides better resistance to wind loading in overhead applications.

Fatigue resistance testing evaluates the conductor's ability to withstand repeated mechanical stresses over time. CCC Wire shows excellent performance in cyclic loading tests that simulate real-world conditions such as thermal expansion and contraction. The balanced construction distributes mechanical stresses effectively, contributing to extended operational life in dynamic installation environments.

Installation and Maintenance Considerations

Installation Best Practices

Proper installation techniques are crucial for realizing the full reliability potential of CCC Wire in power distribution systems. Standard electrical installation practices apply, with particular attention to termination methods and connection integrity. The conductor's mechanical properties may require slight modifications to pulling tensions and bending radii compared to solid copper, but these adjustments are readily accommodated with proper planning.

Termination hardware compatibility ensures reliable connections throughout the system lifecycle. CCC Wire works effectively with standard compression fittings, mechanical connectors, and other termination methods commonly used in power distribution applications. Proper torque specifications and installation procedures help ensure long-term connection reliability and minimize maintenance requirements.

Maintenance Requirements

Long-term maintenance requirements for CCC Wire installations are generally comparable to or less demanding than traditional copper conductor systems. The enhanced corrosion resistance and mechanical durability reduce the frequency of required inspections and maintenance interventions. Regular connection inspections remain important, but the stable electrical and mechanical properties of CCC Wire contribute to more predictable maintenance scheduling.

Diagnostic testing procedures for CCC Wire systems follow established practices for conductor evaluation. Insulation resistance testing, continuity measurements, and thermal imaging provide effective monitoring capabilities for assessing system condition. The consistent electrical properties of CCC Wire facilitate accurate interpretation of test results and trending analysis over time.

Economic and Operational Benefits

Cost-Effectiveness Analysis

The economic advantages of CCC Wire become apparent when evaluating total cost of ownership over the system lifecycle. Initial material costs typically represent savings compared to solid copper conductors, while installation costs may be reduced due to lighter weight and improved handling characteristics. These upfront savings combine with long-term operational benefits to provide attractive project economics.

Operational cost savings result from reduced maintenance requirements, improved system reliability, and extended service life. The enhanced durability of CCC Wire translates to fewer replacement cycles and reduced downtime for maintenance activities. Energy efficiency remains comparable to solid copper systems, ensuring that operational costs remain optimized throughout the installation's service life.

Supply Chain Advantages

Supply chain considerations favor CCC Wire in many applications due to more stable raw material costs and improved availability compared to solid copper products. The reduced copper content provides some insulation from commodity price volatility while maintaining essential electrical performance characteristics. This stability helps project managers develop more predictable budgets and procurement strategies.

Manufacturing capacity for CCC Wire continues to expand as demand grows across various industries. This increased production capability supports reliable delivery schedules and competitive pricing for large-scale power distribution projects. The established supply base provides confidence in material availability for both new installations and future maintenance requirements.

Industry Applications and Case Studies

Commercial and Industrial Installations

Commercial building power distribution systems have successfully incorporated CCC Wire in applications ranging from office complexes to manufacturing facilities. The conductor's reliable performance in HVAC systems, lighting circuits, and industrial machinery demonstrates its versatility across diverse load types. Installation experience shows that CCC Wire meets the demanding requirements of modern commercial electrical systems.

Industrial applications benefit from the enhanced mechanical properties of CCC Wire, particularly in environments with significant vibration, temperature cycling, or corrosive conditions. Process industries have reported successful long-term operation with minimal maintenance requirements. The conductor's performance in motor control circuits and power distribution panels demonstrates its suitability for critical industrial applications.

Utility and Infrastructure Projects

Utility companies have adopted CCC Wire for various distribution system applications where cost-effectiveness and reliability are primary concerns. Overhead distribution lines utilizing CCC Wire have demonstrated acceptable performance over several years of service. The conductor's mechanical strength provides advantages in areas subject to ice loading or high wind conditions.

Infrastructure projects including transportation systems and public facilities have incorporated CCC Wire with positive results. The combination of electrical performance and mechanical durability makes it suitable for demanding infrastructure applications. Long-term monitoring data from these installations provides confidence in the conductor's ability to deliver reliable service over extended periods.

Comparison with Alternative Conductor Technologies

Solid Copper Conductor Comparison

Direct comparison between CCC Wire and solid copper conductors reveals trade-offs that must be evaluated for specific applications. While solid copper provides maximum electrical conductivity, CCC Wire offers comparable performance for most power distribution requirements at reduced material cost. The mechanical advantages of CCC Wire can offset any minor electrical performance differences in many installations.

Installation characteristics differ between the conductor types, with CCC Wire typically offering advantages in weight and handling. The composite construction provides improved resistance to mechanical damage during installation, potentially reducing installation costs and improving project schedules. These practical advantages often outweigh theoretical electrical performance differences in real-world applications.

Aluminum Conductor Alternatives

Aluminum conductors represent another cost-effective alternative for power distribution applications, but CCC Wire offers distinct advantages in certain situations. The copper cladding of CCC Wire provides superior corrosion resistance and connection reliability compared to aluminum. This can be particularly important in coastal or industrial environments where aluminum conductors might experience accelerated degradation.

Termination practices for CCC Wire align more closely with traditional copper conductor methods, reducing the need for specialized hardware or installation procedures. This compatibility advantage can simplify project specifications and reduce training requirements for installation personnel. The familiar handling characteristics of CCC Wire facilitate adoption in organizations with established copper conductor experience.

Technical Standards and Compliance

Industry Standard Conformance

CCC Wire products manufactured to established industry standards provide assurance of consistent quality and performance characteristics. Compliance with relevant ASTM, UL, and international standards ensures that the conductors meet recognized criteria for electrical and mechanical properties. Third-party testing and certification provide independent verification of product specifications and performance claims.

Quality assurance programs implemented by reputable manufacturers include comprehensive testing protocols that verify electrical properties, dimensional accuracy, and mechanical characteristics. These programs ensure that each production lot meets specified requirements and maintains consistency across manufacturing batches. Documentation and traceability systems support quality control and provide confidence in long-term performance.

Installation Code Compliance

Electrical installation codes and standards recognize CCC Wire as an acceptable conductor type for appropriate applications. Compliance with National Electrical Code requirements and local electrical regulations ensures that installations meet safety and performance criteria. Proper application within code limitations helps ensure reliable long-term operation and regulatory compliance.

Engineering specifications for CCC Wire installations should reference applicable standards and installation requirements to ensure proper application. Coordination with local electrical inspectors and engineering authorities helps verify that proposed installations meet all relevant requirements. This regulatory compliance supports confident specification and installation of CCC Wire in power distribution systems.

FAQ

How long can CCC Wire be expected to last in typical power distribution applications

CCC Wire is designed for service life comparable to traditional copper conductors, typically 25-30 years or more in properly installed and maintained systems. The copper cladding provides excellent corrosion protection while the composite construction offers enhanced mechanical durability. Real-world installations with over a decade of service demonstrate stable electrical and mechanical performance, indicating that CCC Wire can meet long-term reliability requirements for power distribution applications.

Does CCC Wire require special installation techniques or equipment

CCC Wire installation follows standard electrical practices with minor adjustments for its mechanical properties. Standard pulling equipment and installation methods work effectively, though pulling tensions may need slight modification compared to solid copper. Termination hardware designed for copper conductors is generally compatible with CCC Wire. Most electrical contractors can install CCC Wire successfully with minimal additional training or specialized equipment.

What are the key factors that affect CCC Wire reliability over time

Long-term reliability of CCC Wire depends primarily on proper installation practices, environmental conditions, and connection integrity. The copper cladding thickness and quality are critical factors that must meet manufacturer specifications. Environmental factors such as moisture, chemical exposure, and temperature cycling can impact performance, but CCC Wire generally shows good resistance to these conditions. Regular inspection of connections and terminations helps ensure continued reliable operation throughout the service life.

How does CCC Wire performance compare to solid copper in high-current applications

CCC Wire performance in high-current applications depends on proper sizing and application within manufacturer specifications. For most power distribution currents, the electrical performance closely matches solid copper due to skin effect phenomena. In very high current applications, thermal management becomes critical and may require careful evaluation of specific installation conditions. Properly designed CCC Wire installations can handle substantial current loads while maintaining acceptable temperature rise and electrical efficiency.

Table of Contents

- Understanding CCC Wire Construction and Technology

- Electrical Performance Characteristics

- Long-Term Reliability Factors

- Installation and Maintenance Considerations

- Economic and Operational Benefits

- Industry Applications and Case Studies

- Comparison with Alternative Conductor Technologies

- Technical Standards and Compliance

-

FAQ

- How long can CCC Wire be expected to last in typical power distribution applications

- Does CCC Wire require special installation techniques or equipment

- What are the key factors that affect CCC Wire reliability over time

- How does CCC Wire performance compare to solid copper in high-current applications