The debate between copper clad aluminum and pure copper in electrical applications has intensified as manufacturers seek cost-effective solutions without compromising performance. Copper clad aluminum represents a hybrid approach that combines aluminum's lightweight properties with copper's superior conductivity characteristics. This innovative material has gained significant traction across various industries, from telecommunications to power transmission systems. Understanding the fundamental differences between these materials is crucial for making informed decisions in cable manufacturing and electrical system design.

Understanding Copper Clad Aluminum Technology

Manufacturing Process and Composition

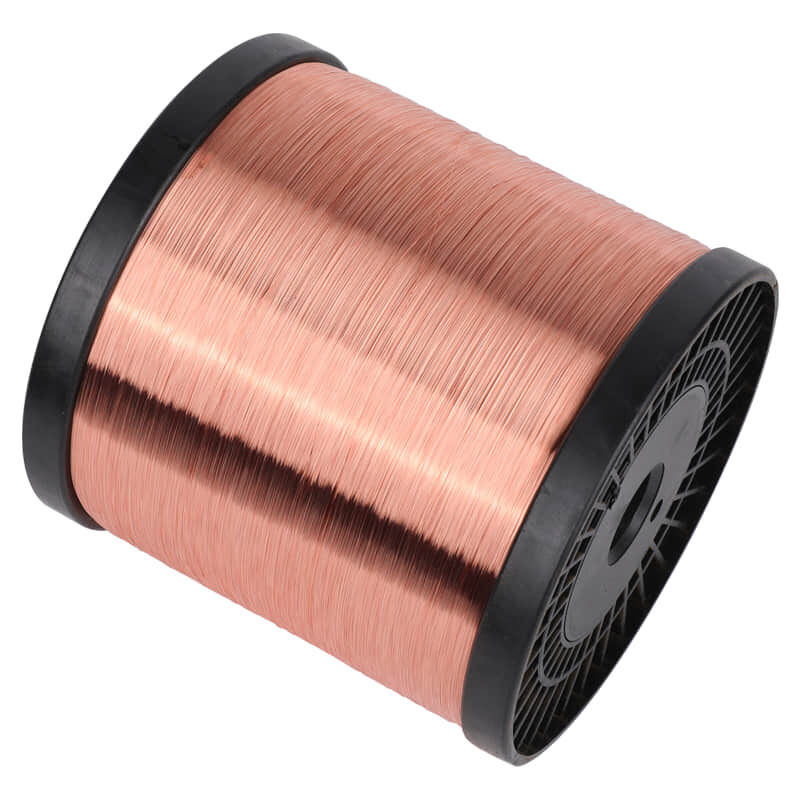

Copper clad aluminum wire consists of an aluminum core surrounded by a thin layer of copper through a specialized bonding process. This manufacturing technique creates a metallurgical bond between the two metals, ensuring consistent electrical and mechanical properties throughout the conductor's length. The copper cladding typically comprises 10-15% of the total cross-sectional area, while aluminum forms the majority of the core structure. This composition provides the optimal balance between conductivity and weight reduction that makes copper clad aluminum attractive for numerous applications.

The production process involves drawing aluminum wire through a series of dies while simultaneously applying copper cladding under controlled temperature and pressure conditions. This method ensures uniform thickness of the copper layer and prevents delamination during handling and installation. Quality control measures throughout manufacturing guarantee that the copper clad aluminum meets strict industry standards for electrical performance and mechanical integrity.

Physical and Electrical Properties

The electrical characteristics of copper clad aluminum differ significantly from both pure aluminum and solid copper conductors. The copper outer layer provides excellent surface conductivity, which is particularly important for high-frequency applications where skin effect becomes prominent. At radio frequencies, current tends to flow primarily through the outer surface of conductors, making the copper cladding highly effective for signal transmission.

Mechanically, copper clad aluminum exhibits properties that fall between aluminum and copper. The material demonstrates improved flexibility compared to solid copper while maintaining better tensile strength than pure aluminum. These characteristics make copper clad aluminum particularly suitable for applications requiring frequent flexing or movement, such as mobile equipment connections and temporary installations.

Comparative Analysis with Pure Copper

Conductivity Performance

Pure copper remains the gold standard for electrical conductivity, offering approximately 100% IACS (International Annealed Copper Standard) conductivity rating. In comparison, copper clad aluminum typically achieves 60-65% IACS conductivity, which still meets requirements for many electrical applications. The conductivity difference becomes less significant in AC applications where skin effect limits current flow to the outer conductor surface.

For DC applications, the conductivity difference between copper clad aluminum and pure copper becomes more pronounced. However, this gap can be compensated by increasing the conductor size, often resulting in overall cost savings despite the larger cable diameter. The performance trade-off must be carefully evaluated based on specific application requirements and installation constraints.

Weight and Installation Advantages

One of the most significant advantages of copper clad aluminum lies in its weight reduction compared to solid copper conductors. Copper clad aluminum cables typically weigh 40-50% less than equivalent copper cables, dramatically reducing installation costs and structural support requirements. This weight advantage becomes particularly important in overhead installations, long cable runs, and applications where weight restrictions apply.

The reduced weight of copper clad aluminum cables simplifies handling during installation and reduces labor costs associated with cable pulling and support structure requirements. Additionally, the lighter weight allows for longer cable runs without intermediate supports, reducing overall installation complexity and material costs in many applications.

Cost-Effectiveness and Economic Considerations

Material Cost Analysis

The economic advantages of copper clad aluminum become apparent when analyzing raw material costs and price volatility. Aluminum prices remain significantly more stable than copper prices, which can fluctuate dramatically based on market conditions and global demand. Copper clad aluminum provides cost predictability that allows for better project budgeting and long-term planning in large-scale installations.

Manufacturing costs for copper clad aluminum are generally lower than solid copper due to reduced copper content, even accounting for the more complex production process. The cost savings become more pronounced in large-diameter cables where the material cost differential has the greatest impact on overall project economics.

Lifecycle Cost Considerations

Beyond initial material costs, copper clad aluminum offers advantages in installation and maintenance expenses. The reduced weight translates to lower shipping costs, easier handling, and reduced installation time. These factors contribute to significant cost savings in large projects where labor and logistics costs represent substantial portions of total project expenses.

Long-term reliability of copper clad aluminum has been proven through decades of successful applications in various industries. When properly installed and maintained, copper clad aluminum systems demonstrate excellent service life comparable to solid copper installations, ensuring that initial cost savings do not come at the expense of long-term reliability.

Application-Specific Performance Evaluation

Telecommunications and Data Applications

In telecommunications applications, copper clad aluminum demonstrates excellent performance characteristics for both analog and digital signal transmission. The copper outer layer provides optimal impedance matching and signal integrity, while the aluminum core reduces cable weight in extensive distribution networks. Copper clad aluminum cables meet or exceed performance requirements for most data transmission standards, including Category 5e and Category 6 specifications.

High-frequency performance of copper clad aluminum makes it particularly suitable for coaxial cable applications, where skin effect ensures that signal transmission occurs primarily through the copper cladding. This characteristic allows copper clad aluminum coaxial cables to achieve performance levels nearly identical to solid copper alternatives while providing significant cost and weight advantages.

Power Distribution Systems

Power distribution applications present unique considerations for copper clad aluminum implementation. The material performs well in medium voltage applications where conductor size can be adjusted to compensate for the conductivity difference compared to solid copper. Copper clad aluminum power cables demonstrate excellent performance in overhead distribution systems, where weight reduction provides substantial structural and economic benefits.

Grounding applications represent another area where copper clad aluminum excels due to the copper surface providing excellent corrosion resistance and low contact resistance. The material meets grounding conductor requirements while offering installation advantages in challenging environments where weight and flexibility considerations are important.

Environmental and Sustainability Factors

Resource Conservation Impact

The environmental benefits of copper clad aluminum extend beyond immediate cost considerations to encompass broader sustainability goals. By reducing copper consumption while maintaining performance standards, copper clad aluminum helps conserve valuable copper resources that require energy-intensive mining and refining processes. This resource conservation contributes to reduced environmental impact throughout the material lifecycle.

Aluminum production, while energy-intensive initially, benefits from highly efficient recycling processes that require significantly less energy than primary production. The aluminum content in copper clad aluminum enhances the recyclability of cables at end-of-life, supporting circular economy principles and reducing waste in electrical infrastructure applications.

Carbon Footprint Considerations

Transportation impacts represent a significant component of cable system carbon footprints, particularly for large installations. The reduced weight of copper clad aluminum cables directly translates to lower transportation emissions and reduced fuel consumption during shipping and installation. These environmental benefits accumulate significantly in large-scale projects involving extensive cable networks.

Manufacturing energy requirements for copper clad aluminum generally result in lower carbon emissions compared to equivalent solid copper products, despite the more complex production process. The overall environmental impact assessment favors copper clad aluminum when considering the complete lifecycle from raw material extraction through end-of-life recycling.

Installation and Maintenance Considerations

Installation Best Practices

Proper installation techniques for copper clad aluminum require specific considerations to ensure optimal performance and longevity. Connection methods must account for the bimetallic nature of the conductor, utilizing appropriate connectors and compounds designed for copper clad aluminum applications. Proper installation practices prevent galvanic corrosion and ensure reliable electrical connections throughout the system lifecycle.

Cable pulling techniques for copper clad aluminum installations benefit from the reduced weight and improved flexibility of the material. Installation crews report easier handling and reduced physical stress during cable pulling operations, leading to improved installation quality and reduced installation time. These advantages translate to lower installation costs and reduced risk of cable damage during installation.

Long-term Maintenance Requirements

Maintenance requirements for copper clad aluminum systems are generally comparable to solid copper installations when proper installation practices are followed. Regular inspection of connections and terminations ensures continued system reliability, with particular attention to environmental factors that might affect bimetallic interfaces. Proper maintenance practices maximize the service life and performance of copper clad aluminum installations.

Troubleshooting copper clad aluminum systems requires understanding of the material's unique characteristics, particularly in connection points and termination areas. Maintenance personnel should be trained on proper testing procedures and repair techniques specific to copper clad aluminum to ensure effective system maintenance and troubleshooting capabilities.

FAQ

What are the main performance differences between copper clad aluminum and pure copper

Copper clad aluminum typically provides 60-65% of the conductivity of pure copper, which is adequate for most applications when conductor size is properly adjusted. The copper outer layer ensures excellent high-frequency performance and corrosion resistance, while the aluminum core reduces weight by 40-50% compared to solid copper. For AC applications, the performance difference is minimal due to skin effect, making copper clad aluminum an excellent alternative to pure copper in many installations.

Can copper clad aluminum be used in residential wiring applications

Copper clad aluminum can be used in residential applications when proper installation practices and appropriate connectors are employed. The material requires specific termination methods and connections rated for copper clad aluminum to prevent reliability issues. While some electrical codes have restrictions on aluminum conductors in residential applications, copper clad aluminum with proper copper cladding thickness may be acceptable under certain conditions and local code requirements.

How does copper clad aluminum perform in high-frequency applications

Copper clad aluminum excels in high-frequency applications due to the skin effect phenomenon, where current flows primarily through the outer surface of the conductor. The copper cladding provides excellent high-frequency conductivity, making copper clad aluminum coaxial cables perform nearly identically to solid copper alternatives. This characteristic makes the material particularly suitable for RF, telecommunications, and data transmission applications where high-frequency performance is critical.

What are the environmental benefits of choosing copper clad aluminum over pure copper

Copper clad aluminum offers several environmental advantages including reduced copper resource consumption, lower transportation emissions due to reduced weight, and enhanced recyclability through the aluminum content. The material helps conserve valuable copper resources while maintaining performance standards, supporting sustainability goals in electrical infrastructure projects. Additionally, the reduced weight leads to lower installation energy requirements and reduced structural support needs, contributing to overall environmental impact reduction.

Table of Contents

- Understanding Copper Clad Aluminum Technology

- Comparative Analysis with Pure Copper

- Cost-Effectiveness and Economic Considerations

- Application-Specific Performance Evaluation

- Environmental and Sustainability Factors

- Installation and Maintenance Considerations

-

FAQ

- What are the main performance differences between copper clad aluminum and pure copper

- Can copper clad aluminum be used in residential wiring applications

- How does copper clad aluminum perform in high-frequency applications

- What are the environmental benefits of choosing copper clad aluminum over pure copper