Corrosion remains one of the most persistent challenges in electrical and telecommunications infrastructure, costing industries billions annually in maintenance and replacement costs. The development of brass clad steel stranded wire represents a significant advancement in combating this pervasive problem. This innovative conductor technology combines the strength of steel with the corrosion resistance of brass, creating a solution that addresses both mechanical durability and environmental protection. Understanding how this specialized wire prevents corrosion requires examining its unique construction, protective mechanisms, and real-world applications across various industries.

Understanding the Construction of Corrosion-Resistant Wire

Core Steel Foundation

The foundation of brass clad steel stranded wire begins with a high-tensile steel core that provides exceptional mechanical strength and durability. This steel core is carefully selected for its ability to withstand significant tension loads while maintaining flexibility necessary for installation and operation. The steel composition typically includes carbon content optimized for strength without compromising workability. Each individual strand undergoes precise manufacturing processes to ensure consistent diameter and surface quality, which are critical factors in achieving uniform brass cladding coverage.

Manufacturing specifications require the steel core to meet stringent standards for tensile strength, elongation, and surface finish. The preparation process involves thorough cleaning and surface treatment to remove any oxides, oils, or contaminants that could interfere with the brass bonding process. Quality control measures ensure that each steel strand meets exact dimensional tolerances, as variations can lead to inconsistent cladding thickness and potential corrosion vulnerabilities.

Brass Cladding Technology

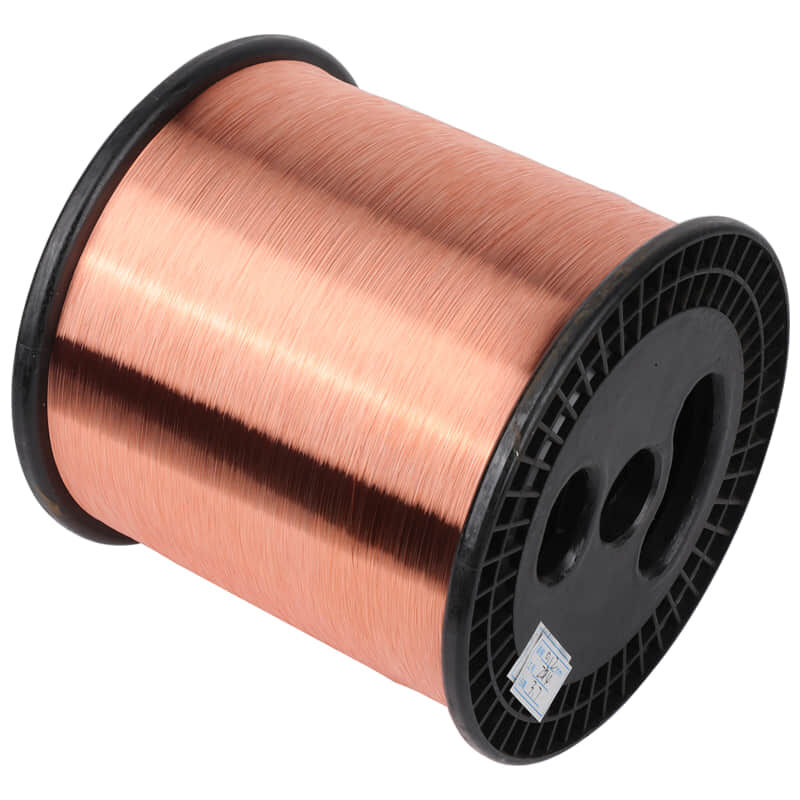

The brass cladding process represents the critical protective element that distinguishes this wire type from conventional steel conductors. Brass, an alloy of copper and zinc, provides superior corrosion resistance compared to bare steel while maintaining excellent electrical conductivity. The cladding process involves metallurgically bonding the brass layer to the steel core through controlled heating and drawing operations that create an intimate molecular connection between the two metals.

Modern cladding techniques ensure uniform thickness distribution around the entire circumference of each strand, eliminating weak points where corrosion could initiate. The brass layer thickness is precisely controlled to provide optimal protection while maintaining cost-effectiveness. This brass clad steel stranded wire construction creates a barrier that prevents moisture and corrosive elements from reaching the underlying steel core, significantly extending service life in challenging environments.

Corrosion Prevention Mechanisms

Galvanic Protection Principles

The corrosion prevention effectiveness of brass clad steel stranded wire relies heavily on galvanic protection principles that create an electrochemical barrier against oxidation. Brass serves as a sacrificial anode in the galvanic series, meaning it will corrode preferentially to the underlying steel core. This sacrificial protection mechanism ensures that even if the brass cladding experiences minor damage, the exposed steel remains protected through electrochemical action.

The galvanic compatibility between brass and steel creates a stable electrochemical environment that inhibits corrosion initiation. Unlike dissimilar metal combinations that can accelerate corrosion through galvanic action, the brass-steel pairing in properly manufactured wire provides protective benefits. The controlled galvanic potential difference ensures long-term stability without excessive brass consumption, maintaining protective integrity throughout the wire's service life.

Environmental Barrier Properties

Brass cladding creates a comprehensive environmental barrier that prevents corrosive agents from contacting the steel substrate. The dense, uniform brass layer effectively blocks moisture penetration, oxygen infiltration, and chemical attack from environmental pollutants. This physical barrier function works in conjunction with the galvanic protection to provide multiple layers of corrosion defense.

The brass surface naturally develops a protective patina over time that further enhances corrosion resistance. This oxide layer acts as an additional barrier against environmental attack while maintaining the underlying brass integrity. The self-healing nature of brass oxidation means that minor surface scratches or abrasions do not compromise the overall protective system, as the exposed brass quickly forms new protective compounds.

Performance in Harsh Environments

Marine and Coastal Applications

Marine environments present some of the most challenging conditions for metallic conductors due to high salt content, moisture, and temperature variations. Brass clad steel stranded wire demonstrates exceptional performance in these conditions, significantly outperforming bare steel and many other conductor types. The brass cladding provides superior resistance to chloride-induced corrosion, which is the primary failure mechanism for steel in marine environments.

Field testing in coastal installations has shown that brass clad steel stranded wire maintains structural and electrical integrity for decades in salt spray conditions that would rapidly degrade conventional steel conductors. The combination of galvanic protection and barrier properties proves particularly effective against the aggressive corrosive action of seawater and salt-laden atmospheric conditions. Maintenance requirements are dramatically reduced compared to alternative conductor materials, resulting in significant lifecycle cost savings.

Industrial and Chemical Environments

Industrial facilities often expose conductors to chemical vapors, temperature extremes, and mechanical stresses that can accelerate corrosion processes. Brass clad steel stranded wire provides reliable performance in these demanding applications, resisting attack from many industrial chemicals and maintaining mechanical properties under stress. The robust construction handles thermal cycling and mechanical vibrations common in industrial settings while preserving corrosion protection.

Chemical processing plants, refineries, and manufacturing facilities benefit from the extended service life and reduced maintenance requirements of brass clad steel stranded wire. The conductor's resistance to sulfur compounds, organic chemicals, and various industrial atmospheres makes it suitable for applications where conventional materials fail prematurely. Installation and replacement costs are minimized through the extended operational life achieved in these challenging environments.

Comparative Analysis with Alternative Materials

Advantages Over Galvanized Steel

While galvanized steel offers some corrosion protection through zinc coating, brass clad steel stranded wire provides superior long-term performance and reliability. Galvanized coatings are relatively thin and can be damaged during installation or operation, leading to rapid corrosion of the underlying steel. The brass cladding thickness and metallurgical bonding create a more robust protective system that maintains integrity under mechanical stress and environmental exposure.

The electrical properties of brass clad steel stranded wire also surpass those of galvanized alternatives. Brass provides better conductivity than zinc, resulting in lower electrical resistance and improved signal transmission characteristics. This performance advantage becomes increasingly important in high-frequency applications and power transmission systems where efficiency and signal quality are critical factors.

Benefits Compared to Copper Alternatives

Pure copper conductors offer excellent electrical properties but lack the mechanical strength and cost-effectiveness of brass clad steel stranded wire. The steel core provides significantly higher tensile strength, allowing for longer spans and reduced support requirements in overhead installations. This mechanical advantage translates to reduced installation costs and improved system reliability in applications requiring high strength-to-weight ratios.

Cost considerations also favor brass clad steel stranded wire in many applications, as the steel core reduces material costs while the brass cladding provides adequate electrical performance for most applications. The corrosion resistance approaches that of pure copper in many environments while offering superior mechanical properties and economic advantages that make it attractive for large-scale installations.

Installation and Maintenance Considerations

Proper Installation Techniques

Successful corrosion prevention with brass clad steel stranded wire requires adherence to proper installation practices that preserve the integrity of the brass cladding. Installation procedures must minimize mechanical damage to the protective layer while ensuring secure electrical connections. Specialized tools and techniques may be required to avoid scoring or scraping the brass surface during handling and termination.

Connection methods should be compatible with brass surfaces to prevent galvanic corrosion at termination points. Appropriate connector materials and protective compounds help ensure long-term reliability at connection interfaces. Installation personnel require training on the unique characteristics of brass clad steel stranded wire to maximize the corrosion protection benefits and avoid common installation errors that could compromise performance.

Long-Term Maintenance Requirements

One of the significant advantages of brass clad steel stranded wire is the reduced maintenance requirements compared to alternative conductor materials. The robust corrosion protection minimizes the need for frequent inspection and replacement, resulting in lower lifecycle costs. Routine maintenance typically involves visual inspection for mechanical damage and verification of electrical continuity rather than corrosion-related interventions.

When maintenance is required, the brass cladding allows for local repairs and protective treatments that can extend service life further. The self-healing properties of brass oxidation mean that minor surface damage often does not require immediate attention, allowing maintenance schedules to be optimized for operational efficiency rather than emergency response to corrosion failures.

FAQ

What is the typical lifespan of brass clad steel stranded wire in outdoor applications

The lifespan of brass clad steel stranded wire in outdoor applications typically ranges from 30 to 50 years, depending on environmental conditions and installation quality. In moderate climates with proper installation, the wire can exceed 40 years of service life. Harsh marine or industrial environments may reduce this to 25-30 years, which still significantly exceeds the performance of bare steel or galvanized alternatives. The robust brass cladding and galvanic protection mechanisms ensure consistent performance throughout the service life.

How does temperature affect the corrosion protection properties of brass cladding

Temperature variations generally have minimal impact on the corrosion protection properties of brass cladding within normal operating ranges. Brass maintains its protective characteristics from sub-zero temperatures to over 200 degrees Celsius. However, extreme temperature cycling can cause differential expansion between the brass and steel, potentially creating stress points. Proper manufacturing techniques ensure adequate bonding strength to withstand normal thermal cycling without compromising the protective integrity of the cladding system.

Can brass clad steel stranded wire be used in underground applications

Yes, brass clad steel stranded wire is well-suited for underground applications, particularly in corrosive soil conditions. The brass cladding provides excellent resistance to soil chemicals, moisture, and microbial attack that commonly affect buried conductors. However, proper burial depth, backfill materials, and cathodic protection systems may be recommended in highly corrosive soils. The wire should be installed with appropriate protective conduits or direct burial ratings depending on local soil conditions and electrical codes.

What installation precautions are necessary to maintain corrosion protection

Installation precautions include using appropriate tools that won't damage the brass cladding, avoiding excessive bending radii that could crack the protective layer, and ensuring proper connection techniques with compatible materials. Installation crews should be trained to handle the wire carefully during pulling and termination operations. All connections should use corrosion-resistant materials and appropriate sealants to prevent moisture ingress. Regular inspection during installation helps identify any damage that could compromise long-term corrosion protection performance.

Table of Contents

- Understanding the Construction of Corrosion-Resistant Wire

- Corrosion Prevention Mechanisms

- Performance in Harsh Environments

- Comparative Analysis with Alternative Materials

- Installation and Maintenance Considerations

-

FAQ

- What is the typical lifespan of brass clad steel stranded wire in outdoor applications

- How does temperature affect the corrosion protection properties of brass cladding

- Can brass clad steel stranded wire be used in underground applications

- What installation precautions are necessary to maintain corrosion protection