Understanding the Revolutionary Material Transforming Modern Construction

In the ever-evolving world of construction and building materials, aluminum plastic composite has emerged as a game-changing innovation that combines the best properties of both aluminum and plastic. This versatile material consists of two aluminum sheets bonded to a polyethylene core, creating a lightweight yet durable composite that's revolutionizing multiple industries. From sleek building facades to interior design elements, this remarkable material continues to gain popularity among architects, designers, and manufacturers worldwide.

The Composition and Manufacturing Process

Core Material Structure

At its heart, aluminum plastic composite features a sandwich-like construction. The outer layers consist of aluminum sheets, typically ranging from 0.2mm to 0.5mm in thickness, while the inner core is made of polyethylene or other thermoplastic materials. This unique combination results in a material that's significantly lighter than solid aluminum yet maintains exceptional strength and durability. The manufacturing process ensures a strong bond between the layers, creating a unified material that can withstand various environmental conditions.

The polyethylene core plays a crucial role in the material's performance. It not only reduces the overall weight but also provides thermal insulation and sound dampening properties. The core material can be modified with different additives to enhance specific characteristics such as fire resistance or structural integrity, making aluminum plastic composite adaptable to various applications.

Production Techniques

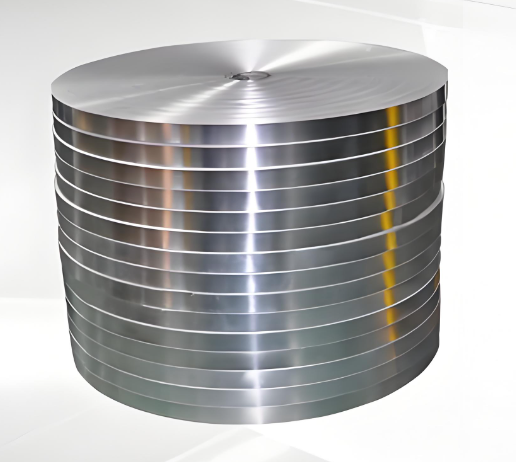

The manufacturing of aluminum plastic composite involves a sophisticated continuous roll-bonding process. The aluminum sheets are first treated with special coatings to ensure proper adhesion to the core material. The polyethylene core is then sandwiched between the treated aluminum sheets and passed through heated rollers under precise pressure and temperature conditions. This process creates a permanent bond between the layers, resulting in a solid, unified panel.

Quality control during production is paramount, with manufacturers implementing strict testing protocols to ensure consistency in thickness, bond strength, and surface finish. Advanced production facilities utilize automated systems to monitor and adjust processing parameters, guaranteeing uniform quality across large production runs.

Key Properties and Advantages

Physical Characteristics

The remarkable properties of aluminum plastic composite make it an ideal choice for numerous applications. The material exhibits excellent strength-to-weight ratio, with panels being up to 60% lighter than solid aluminum sheets of comparable strength. This lightweight nature significantly reduces installation costs and structural load requirements in building applications.

Weather resistance is another standout feature, as the aluminum outer layers provide excellent protection against UV radiation, moisture, and temperature fluctuations. The material maintains its appearance and structural integrity even after years of exposure to harsh environmental conditions, making it particularly suitable for exterior applications.

Performance Benefits

In terms of performance, aluminum plastic composite offers exceptional flatness and dimensional stability. The material resists warping, buckling, and oil-canning effects commonly seen in traditional metal panels. Its thermal expansion rate is significantly lower than solid aluminum, reducing the need for complex expansion joint systems in large installations.

The material also demonstrates impressive acoustic properties, with the polyethylene core helping to reduce sound transmission. This makes it particularly valuable in commercial and residential buildings where noise reduction is a priority. Additionally, the composite structure provides better thermal insulation compared to solid metal panels, contributing to improved energy efficiency in buildings.

Applications Across Industries

Architectural and Construction Uses

The construction industry has embraced aluminum plastic composite as a preferred material for exterior cladding and facades. Its combination of aesthetics and performance makes it ideal for modern architectural designs. The material can be easily formed into various shapes and sizes, allowing architects to create innovative building envelopes with clean lines and smooth surfaces.

Interior applications are equally diverse, ranging from wall panels and column covers to ceiling elements and decorative features. The material's ability to be finished in virtually any color or texture, including wood grain and metallic effects, provides designers with unlimited creative possibilities.

Transportation and Industrial Applications

In the transportation sector, aluminum plastic composite finds extensive use in vehicle body panels, interior partitions, and signage. The material's lightweight nature contributes to improved fuel efficiency, while its durability ensures long-term performance under demanding conditions. Marine applications benefit from the material's corrosion resistance and low maintenance requirements.

Industrial applications include machine enclosures, clean room panels, and equipment housing. The material's ease of fabrication and assembly makes it cost-effective for large-scale industrial projects, while its clean appearance and easy maintenance contribute to operational efficiency.

Installation and Maintenance Considerations

Installation Methods

Professional installation of aluminum plastic composite requires careful attention to detail and proper techniques. The material can be installed using various systems, including rout and return methods, wet seal systems, and dry gasket approaches. Proper planning for thermal expansion and ensuring adequate ventilation behind panels are crucial aspects of successful installation.

Specialized tools and equipment are typically required for cutting and forming the material. While the composite can be worked with standard woodworking and metalworking tools, specific techniques must be followed to achieve clean cuts and precise bends without compromising the material's integrity.

Maintenance Requirements

One of the most appealing aspects of aluminum plastic composite is its minimal maintenance needs. Regular cleaning with mild soap and water is usually sufficient to maintain its appearance. The material resists staining and graffiti, and any surface scratches can often be repaired using simple techniques.

Long-term maintenance considerations include periodic inspection of joints and fasteners, particularly in exterior applications. The material's durability typically results in a long service life with minimal intervention required, making it a cost-effective choice for both commercial and residential projects.

Frequently Asked Questions

Can aluminum plastic composite be recycled?

Yes, aluminum plastic composite can be recycled through specialized processes that separate the aluminum layers from the polyethylene core. Many manufacturers offer recycling programs for their products, contributing to sustainable building practices.

How does the cost compare to traditional building materials?

While the initial material cost may be higher than some traditional options, aluminum plastic composite often proves more economical when considering its long lifespan, reduced maintenance requirements, and lower installation costs due to its lightweight nature.

What is the typical lifespan of aluminum plastic composite panels?

When properly installed and maintained, aluminum plastic composite panels can last 20-30 years or more. The material's resistance to weathering, UV radiation, and corrosion contributes to its exceptional longevity in both exterior and interior applications.