Understanding the Evolution of Electrical Wiring Solutions

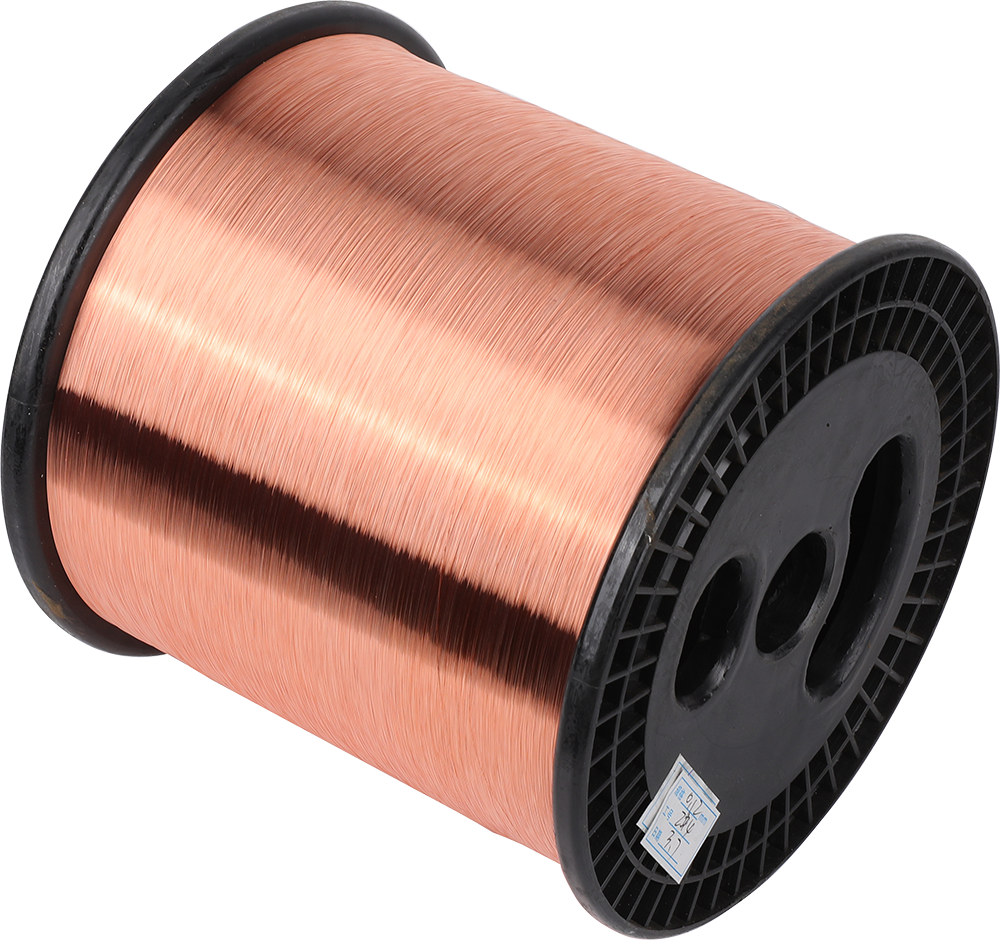

The electrical industry has witnessed significant transformations over the decades, with various conducting materials emerging to meet growing demands. CCA wire, or Copper Clad Aluminum wire, has gained attention as an alternative to traditional copper wiring, particularly in applications where cost-effectiveness meets performance requirements. This innovative solution combines an aluminum core with a copper outer layer, promising the best of both materials while addressing modern electrical needs.

As construction costs continue to rise and copper prices fluctuate, many professionals and homeowners are exploring CCA wire as a potential solution. The material represents a technological advancement that aims to balance performance, affordability, and practical application in various electrical systems.

Technical Composition and Properties of CCA Wire

Manufacturing Process and Material Structure

CCA wire is manufactured through a sophisticated metallurgical bonding process where aluminum core is permanently bonded with a copper outer layer. This process ensures the two metals form a stable, unified conductor. The copper coating typically comprises about 10-15% of the wire's total cross-section, while the aluminum core makes up the remainder. This unique composition allows for optimal electrical conductivity while maintaining cost efficiency.

The production involves precise temperature control and pressure application to achieve a permanent molecular bond between the two metals. This careful manufacturing process is crucial for ensuring the wire's long-term stability and performance reliability.

Electrical Conductivity and Performance Characteristics

When examining CCA wire's electrical properties, it's important to note that it offers approximately 65% of the conductivity of pure copper wire. While this might seem like a significant reduction, the wire is designed with appropriate gauge sizing to compensate for this difference. The aluminum core provides excellent current-carrying capabilities, while the copper coating ensures superior connectivity and corrosion resistance.

Temperature handling capabilities of CCA wire are also noteworthy, though they differ slightly from pure copper. The material can safely handle standard household and commercial electrical loads when properly sized and installed according to relevant electrical codes.

Cost Benefits and Economic Considerations

Initial Investment and Long-term Value

One of the most compelling advantages of CCA wire is its cost-effectiveness. Generally, CCA wire can cost 30-40% less than equivalent pure copper options, making it an attractive choice for budget-conscious projects. This initial cost saving can be substantial, especially in large-scale installations or when wiring entire buildings.

However, the long-term value proposition must consider factors beyond initial purchase price. This includes potential replacement costs, maintenance requirements, and overall system efficiency over time. While CCA wire offers immediate savings, careful consideration of the application requirements ensures the most economical choice.

Market Price Stability and Availability

CCA wire prices tend to be more stable than pure copper, which can experience significant market fluctuations. This price stability makes project budgeting more predictable and reliable. Additionally, the reduced dependency on pure copper helps mitigate supply chain challenges that can affect traditional copper wire availability.

The growing acceptance of CCA wire in various applications has led to improved availability and a wider selection of products from manufacturers. This increased market presence has also contributed to more competitive pricing and better quality control standards.

Installation Considerations and Best Practices

Proper Installation Techniques

Installing CCA wire requires attention to specific details that differ from traditional copper wire installation. The material's slightly different mechanical properties mean that proper termination techniques are crucial. Installers must use appropriate connectors and terminals designed for CCA wire to ensure reliable connections.

Special consideration must be given to the bending radius and pulling tension during installation. While CCA wire is generally flexible and workable, excessive stress during installation should be avoided to maintain the integrity of the copper-aluminum bond.

Code Compliance and Safety Standards

When using CCA wire, adherence to local electrical codes and safety standards is paramount. Most jurisdictions have specific requirements regarding where and how CCA wire can be used. It's essential to verify compliance with current regulations and ensure proper sizing according to ampacity tables specific to CCA wire.

Professional installation by qualified electricians who understand CCA wire's characteristics helps ensure safe and reliable performance. This includes proper grounding practices and appropriate circuit protection measures.

Applications and Limitations

Suitable Use Cases

CCA wire excels in many applications, particularly in low-voltage systems and specific commercial installations. It's commonly used in telecommunications, data communications, and some residential applications where code permits. The material performs well in controlled environments where temperature variations are moderate and moisture exposure is limited.

Some specific areas where CCA wire has proven effective include security systems, audio installations, and certain types of industrial control circuits. Its combination of cost-effectiveness and performance makes it particularly suitable for these applications.

Limitations and Restricted Applications

Despite its advantages, CCA wire isn't suitable for every application. It's generally not recommended for high-temperature environments or applications requiring frequent flexing. Some electrical codes restrict its use in certain critical systems or where maximum conductivity is essential.

Understanding these limitations is crucial for making informed decisions about using CCA wire. Careful evaluation of the specific application requirements helps ensure appropriate material selection and long-term success.

Frequently Asked Questions

How does the lifespan of CCA wire compare to pure copper wire?

When properly installed and maintained, CCA wire can provide reliable service for many years. While its theoretical lifespan might be slightly shorter than pure copper, following proper installation practices and using it within its rated specifications ensures long-term reliability. Regular inspection and maintenance help maximize its service life.

Can CCA wire be used in all electrical installations?

CCA wire is not universally applicable for all electrical installations. Its use is governed by local electrical codes and specific application requirements. It's essential to consult current regulations and professional electricians to determine if CCA wire is suitable for your particular needs.

What are the key maintenance requirements for CCA wire?

CCA wire requires similar maintenance to other electrical wiring systems. Regular inspection of connections, monitoring for signs of oxidation or stress, and ensuring proper environmental conditions help maintain optimal performance. Any issues should be addressed by qualified professionals to ensure safety and reliability.